|

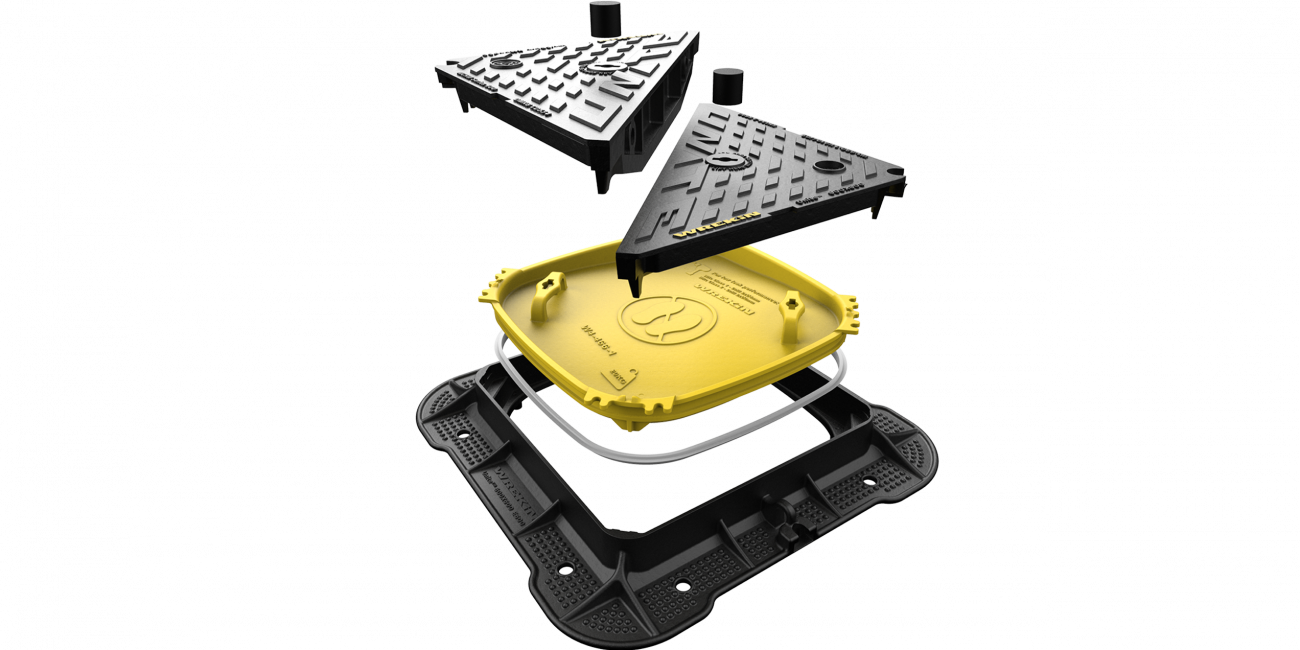

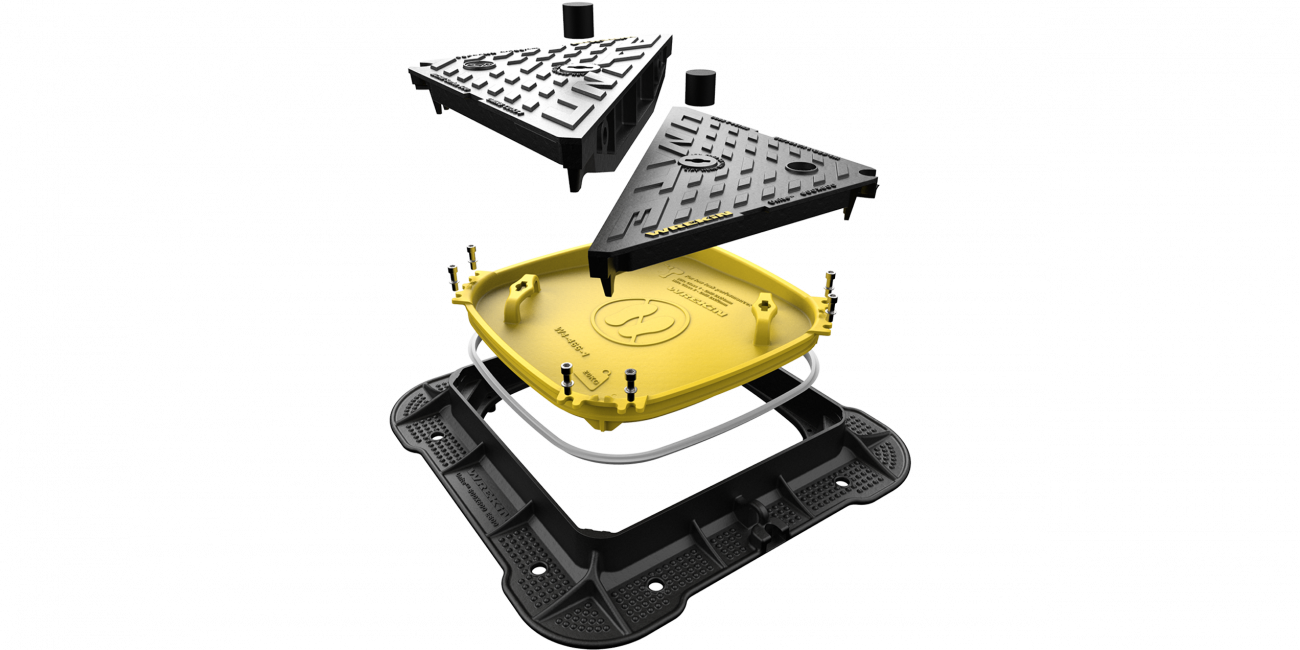

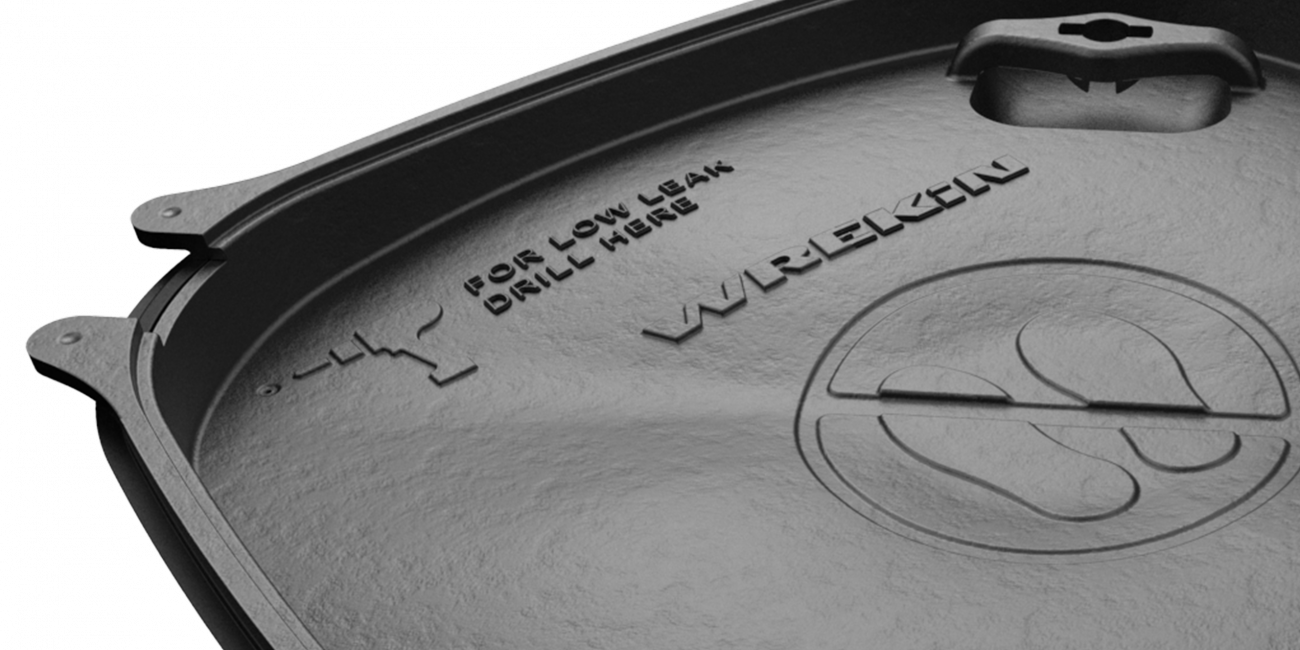

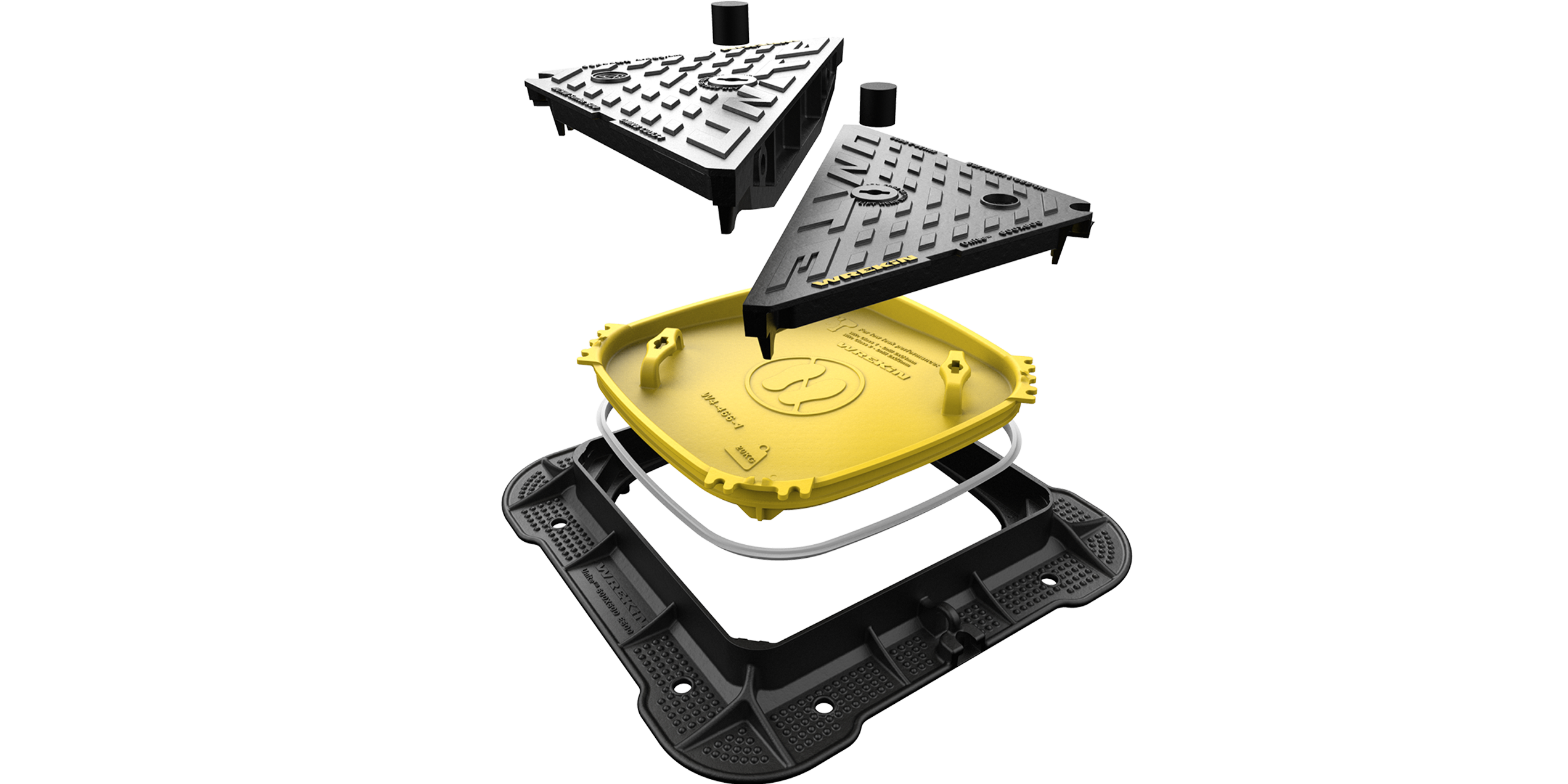

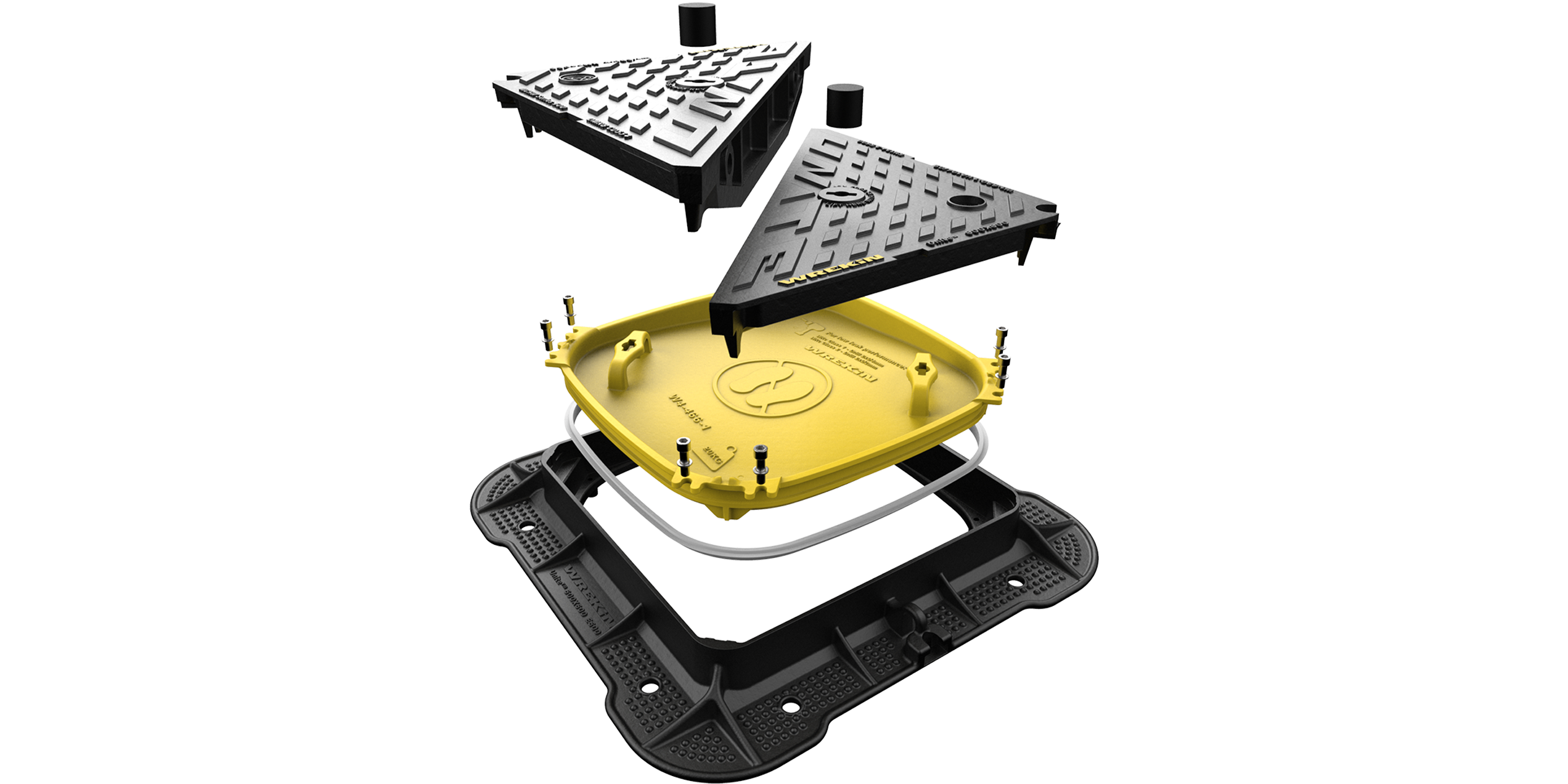

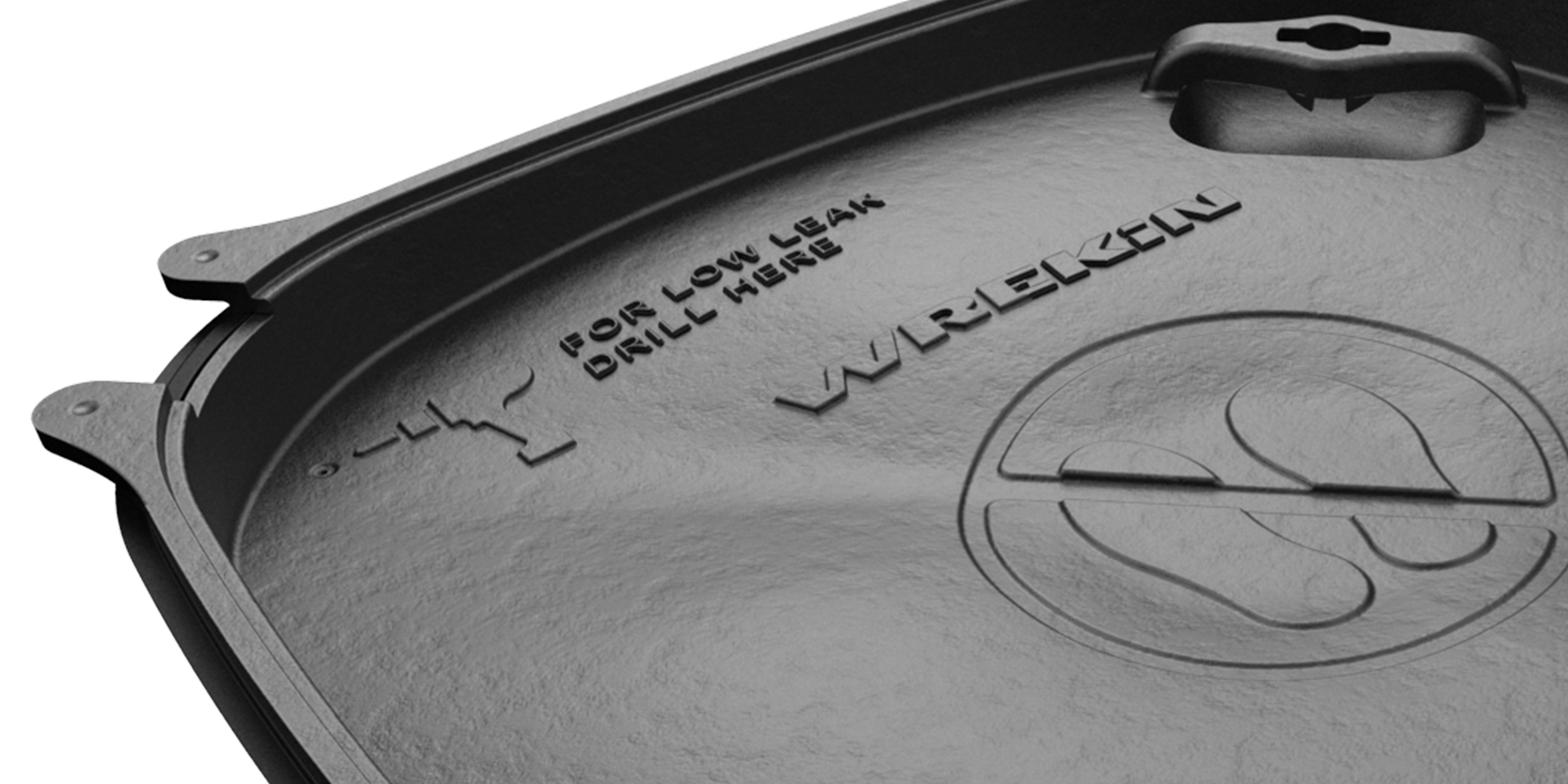

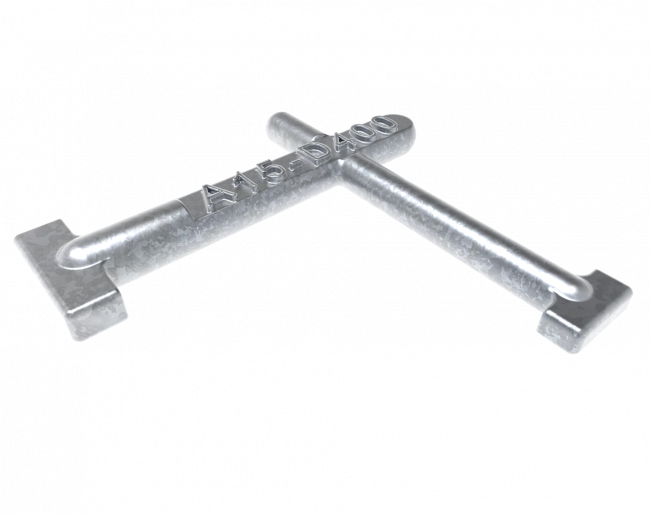

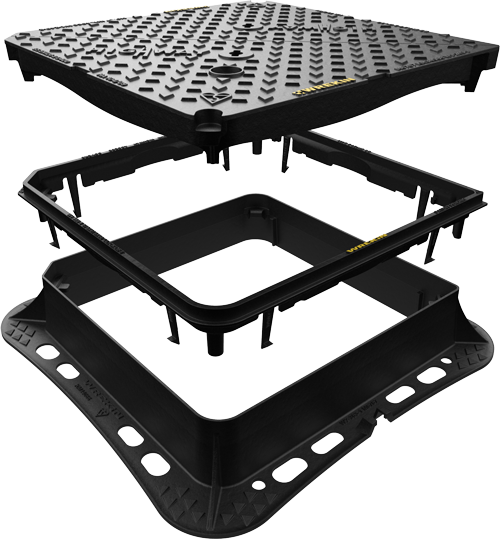

Seal plates are often exposed to harsh environments including potentially corrosive chamber condensates. Retrofittable seal plates are manufactured from ductile iron, which sets it apart from the competition. Alternatives are often manufactured from GRP, which allows corrosion to form between the plate and frame. In fact, other materials can even accelerate corrosion. Our ductile iron assembly provides the best corrosion resistance, as the covers, frames and seal plates are all made from the same material. Although we don’t condone their use as working platforms, in-situ seal plates are structurally superior to GRP variants in sustaining loads from operatives standing on them, providing a significant health and safety benefit if the worst should occur (particularly over deep chambers). The ductile iron seal plate provides active resistance to chamber pressures in comparison to lighter alternatives. Optionally, retrofittable seal plates can be factory bolted so that they demonstrate chamber pressure resistance. The no leak seal plate achieves a WRC Class 3 leakage classification of 0.8 Litres/hour/m². Products

How low-leak manhole covers could be key in flooding controlsAs climate change increases the likelihood of heavy rainfall that can lead to localised flooding in many parts of the UK, and with the resulting pressure on our sewers, the drainage solutions sector has an essential role to play in supporting our infrastructure. Our country’s infrastructure is not fit to deal with weather extremes such as heavy rainfall, which can cause local flooding events – and the more that occurs, the more vulnerable the manhole cover installations on our drainage network will become. A simple solution could be the use of consistent low-leak manhole covers to slow down the amount of surface water entering sewers during a storm. We believe UK’s Sewers for Adoption regulations – which govern the standards needed for installing sewage and wastewater systems – ideally need to quantify the amount of acceptable leakage levels through manhole covers, as well as specifying the mandatory use of low leak apparatus on foul-only sewers.

Why are low-leak manhole covers so important?Low-leak manhole covers allow water to percolate in, slowly and controlled, rather than all at once – which allows the sewer systems to deal with the smaller additional volume. Low leak covers are currently specified rather than fully sealed ones, but the latter prevents any water from entering and contributes to surface flooding. This lack of drainage also results in ‘ponding’ around the cover, which is a traffic hazard and accelerates the corrosion of the manhole covers. It can also be a cause of potholes forming in and around the manhole cover.

What are the issues?Water enters the sewer systems through a number of leakage pathways, including manhole cover chamber openings. These openings are required to be a ‘low-leak’ type, under Water UK’s controlling standard, but they don’t specify what the leakage level should be. An unrestricted flow of water can cause internal flooding that overwhelms the pumping stations, for example. It has to be let out somewhere, often resulting in an emergency fall-out of sewage into national waterways. Are low-leak covers commonplace?They are generally available from most UK suppliers but often need to be specified from the start as the assembly is usually a factory fitment. Furthermore, enquiries for these accessories often don’t equate to the number of covers intended for use on sewer systems. Thankfully, as well as the factory-fit low leak seal plate we offer, we’ve also developed a retrofit design. The retrofit design means the seal plate can be added later if a client realises their site is vulnerable. Indeed, leakage through these features can be as low as 0.8 litres/m2/hour. How can the industry be encouraged to adopt covers fit for purpose?I believe there are three approaches. Firstly, whoever owns manhole cover assets needs to check individual installations for any applicable low-leak requirements – including their current capability – and seek to either source the low-leak feature or replace their cover assemblies where a vulnerability is discovered. Secondly, the Sewers for Adoption (The Code) regulations need to be more specific about the meaning of ‘low-leak’ when referring to manhole covers fitted on foul-only sewer systems. Currently, it specifies low leak capability for such systems but fails to quantify what this means in volume leakage terms. Due to this ambiguity, it’s currently left to the manufacturer's discretion as to what constitutes a suitable low-leak feature. And thirdly, the government needs to consider implementing robust policing of relevant legislation that ensures low-leak features are used as a matter of course on foul-only sewers which, of course, is then likely to result in them becoming more economical to fit. Irrespective of this, it’s encouraging to see so much government and industry discussion around the issues of climate change and flooding, and a review of water utility specifications to ensure the inclusion of low leakage equipment on foul sewers can only improve the situation for all of our benefit. More available accessories

| |||||||||||||||||||||