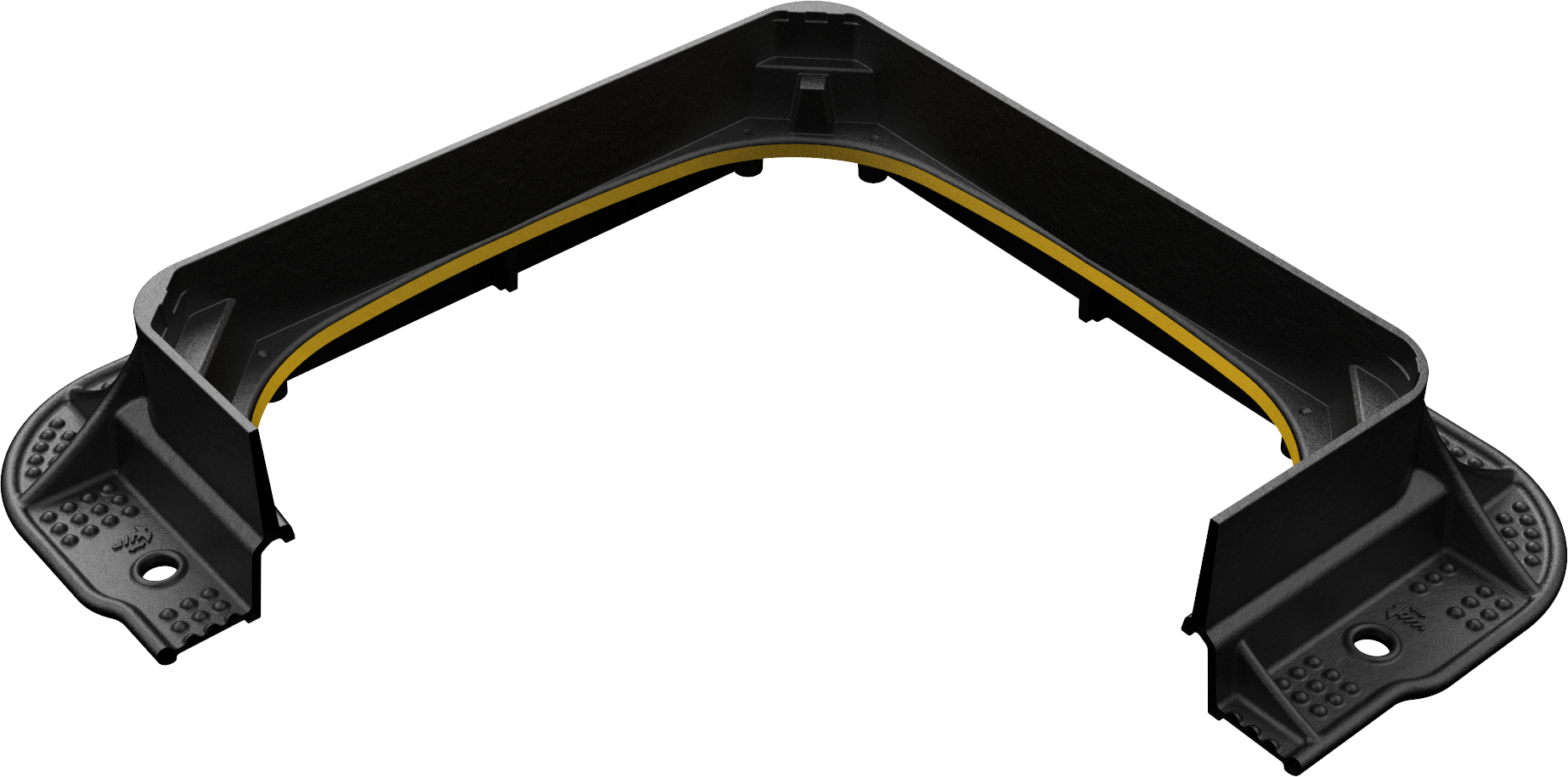

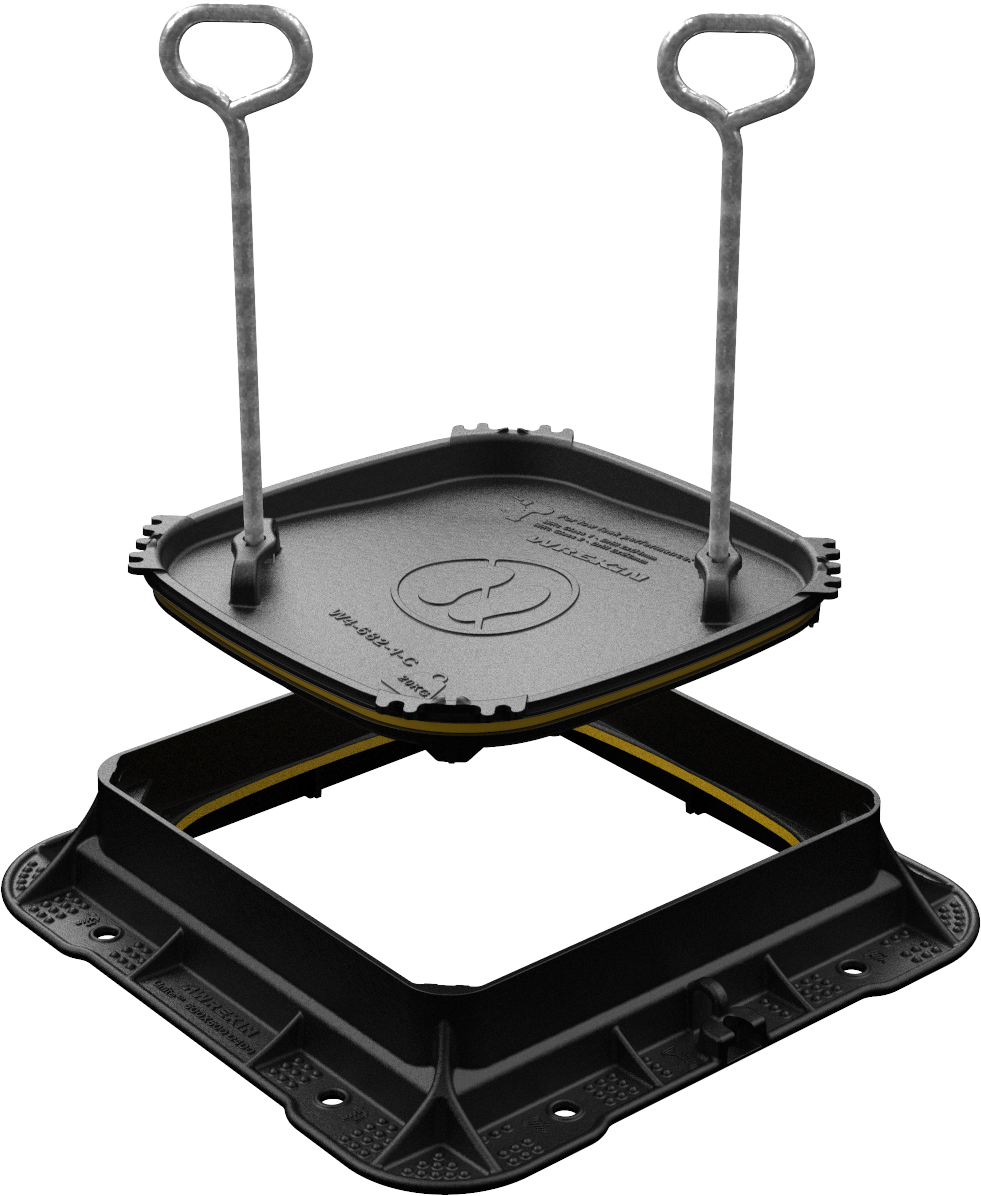

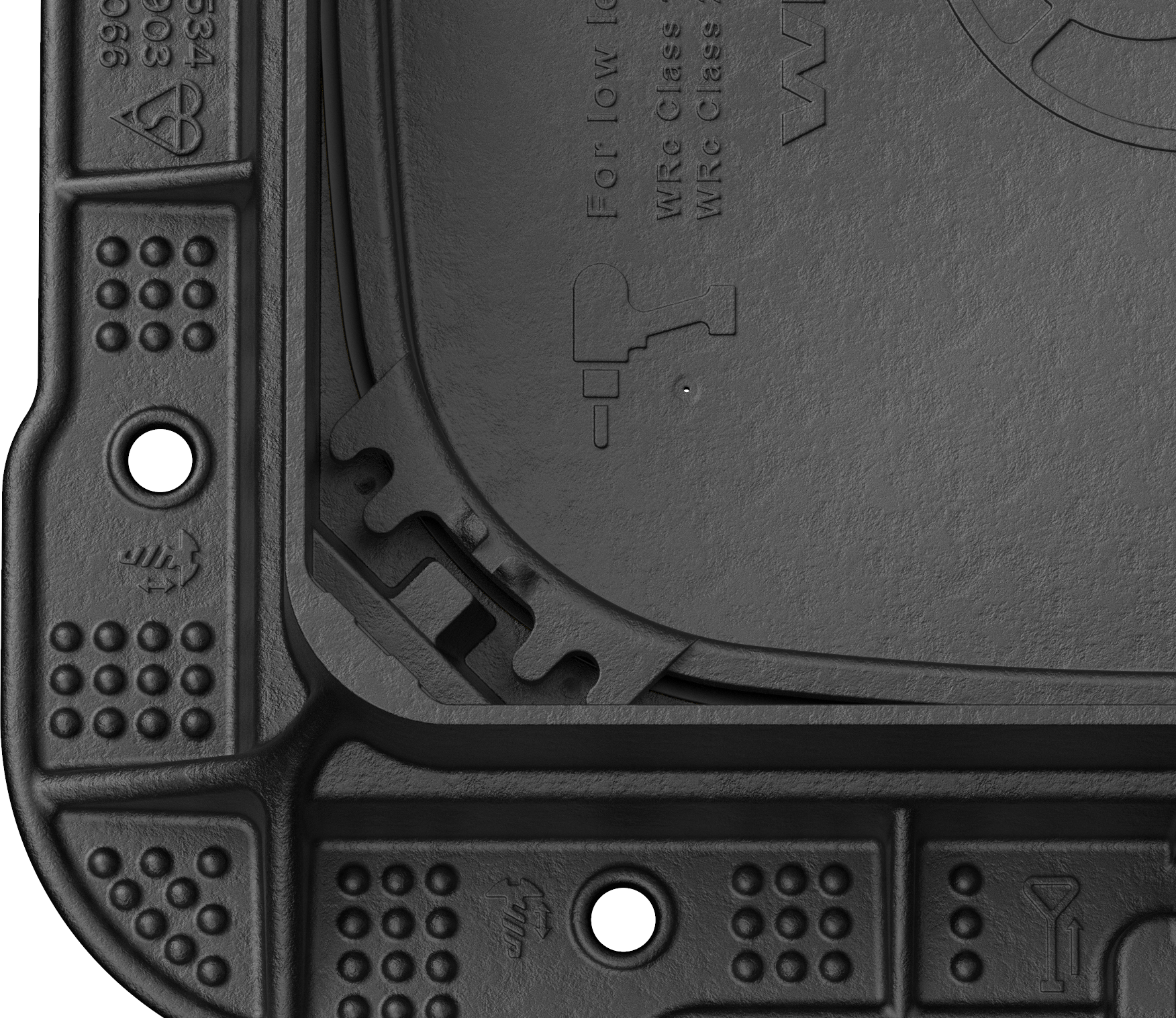

Seal plate installation guideIntroductionUnite's (references ending /KUE) dedicated seal plates are unique to the industry as all but one* variant can be retrofitted on site after installation of the Unite manhole cover assembly. This means the seal plates can be ordered after the manhole cover assemblies which therefore offers installers more time to identify which chamber installations require seal plate fitment (due to their vulnerability to potential future flood water ingress). The Unite seal plates themselves are manufactured from the same grade of spheroidal graphite cast iron as the Unite manhole cover assemblies, and therefore offer industry-leading durability to corrosion resistance. Retro-fit Seal Plates – Low Leak and No Leak (not the chamber-pressure-resistant variant*) This method assumes supply of seal plates after installation of their respective Unite (references ending /KUE) manhole cover assemblies. *The ‘chamber-pressure-resistant’ Seal Plate variant requires factory-fitment and, hence, ordering at point of order placement for Wrekin’s fitment to its respective Unite Evo manhole cover assembly. Step 1Conduct a risk assessment to determine the preferred lifting tooling/equipment for removal of the loose-linked pair of manhole cover elements and temporarily remove the latter from the in-situ frame. Step 2 Identify and clean the in-situ frame’s sealing face of any dirt/debris that might otherwise compromise the Seal Plate’s sealing effectiveness. Step 3 Lightly coat the seal plate’s in-situ rubber seal with a grease compatible with; EPDM elastomers and drinking water (e.g. a grease compliant to BS 6920). Step 4 Using BS 7903 Large-profile long-shank lifting keys inserted into the Seal Plates lifting keyways, place the seal plate centrally into the in-situ frame (and aligning any one-way-fit features on both the in-situ frame and seal Plate), then manually press down (<20Kg) on the seal plate to ensure the sealing rubber is firmly seated in place. Correct indexing

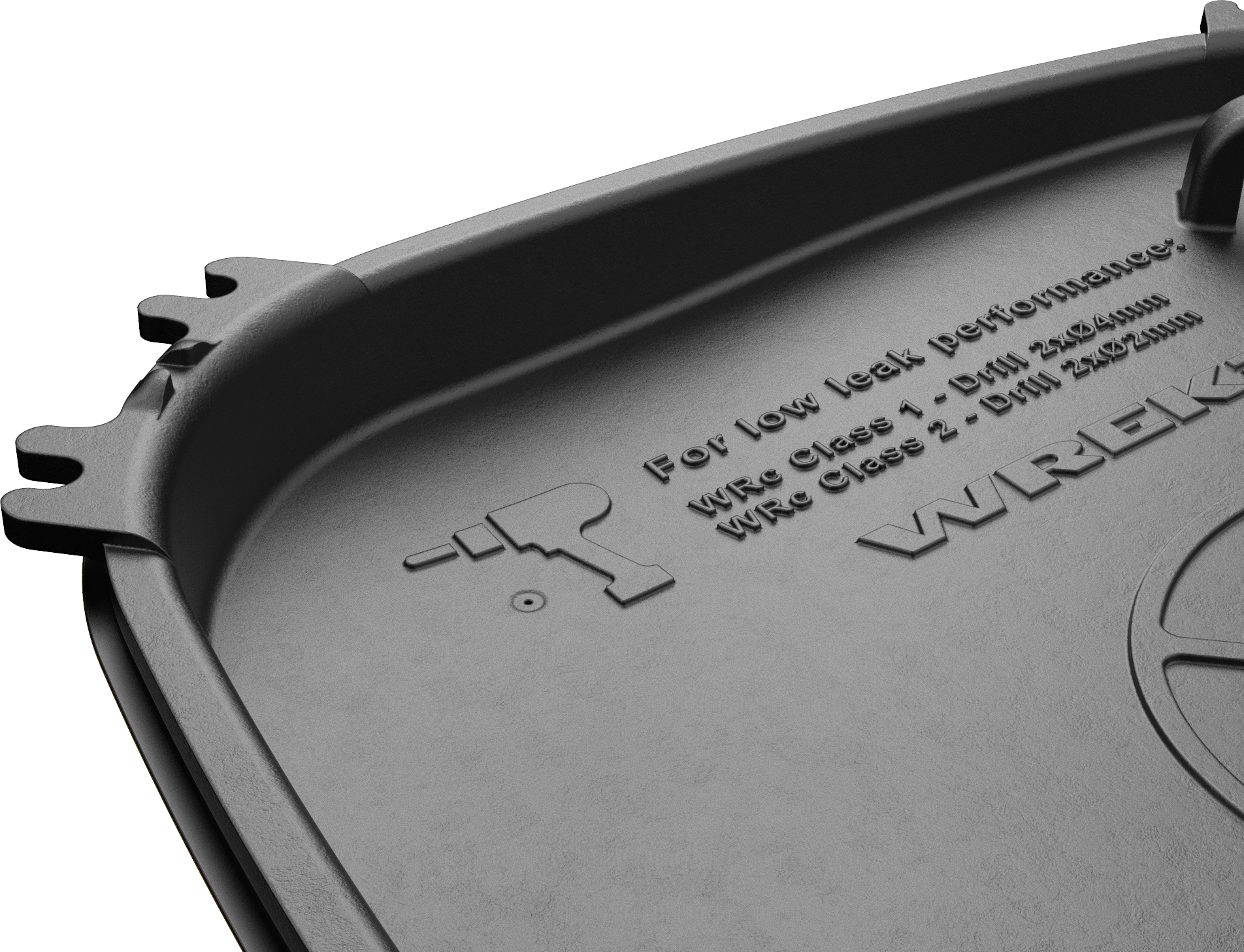

Incorrect indexing Step 5Re-introduce the Unite cover elements back into the in-situ frame using the preferred lifting tooling/equipment. This completes the install method for No Leak variants.  Step 6For low leak variants only Using suitable equipment, drill 2nr holes in the seal plate at the two marked drilling positions (using the drill sizes stated thereon) to achieve the necessary WiS 4-26-1 classification (Class 1 or 2). Step 7For low leak variants onlyRe-introduce the Unite Evo cover elements back into the in-situ Frame using the preferred lifting tooling/equipment.  This completes the install method for Low Leak variants. Related products

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||