|

CD 534: Chamber Tops and Gully Tops for Road Drainage and Services, now at version 0.2.0. is here Find out more

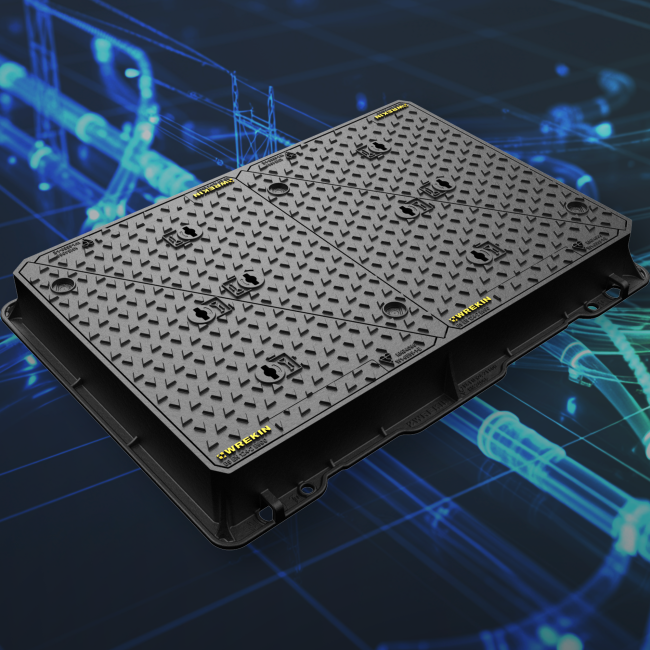

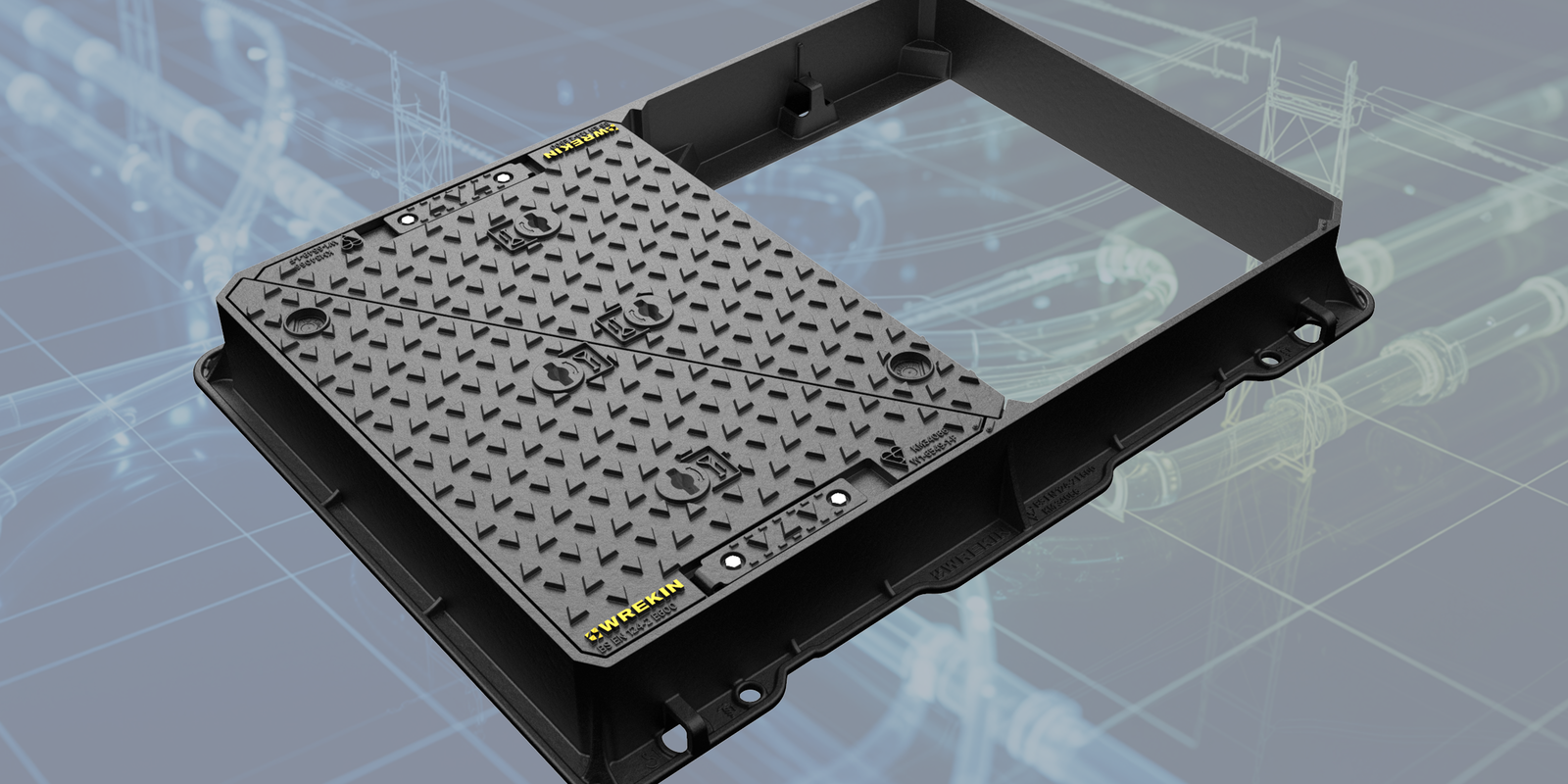

A new generation of designPulse E600 redefines performance in carriageway installations with a bold new design built around an innovative inverted T-flange system†. Engineered for lasting structural integrity and seamless compatibility with reinstatement materials, Pulse delivers exceptional stability while reducing the need for costly, carbon-heavy maintenance. The result? Lower whole-life costs and a greener footprint for every network. Developed through one of the most rigorous client-led testing programmes we’ve ever undertaken, Pulse has been proven under real-world conditions. From bedding mortar stress analysis and impact resistance trials to intensive field simulations, every test pushed Pulse beyond the requirements of BS EN 124-2 and CD 534 v0.2.0. Embedded stress monitoring and repeated impact loading confirmed what we set out to achieve, uncompromising durability and reliability. Backed by verified Environmental Product Declarations (EPDs), Pulse offers measurable sustainability and long-term value. Its structurally balanced design, reinforced by the inverted T-flange, ensures consistent performance in high-intensity carriageway applications, giving asset owners confidence in a solution that’s built to last and designed to protect both budgets and the environment.

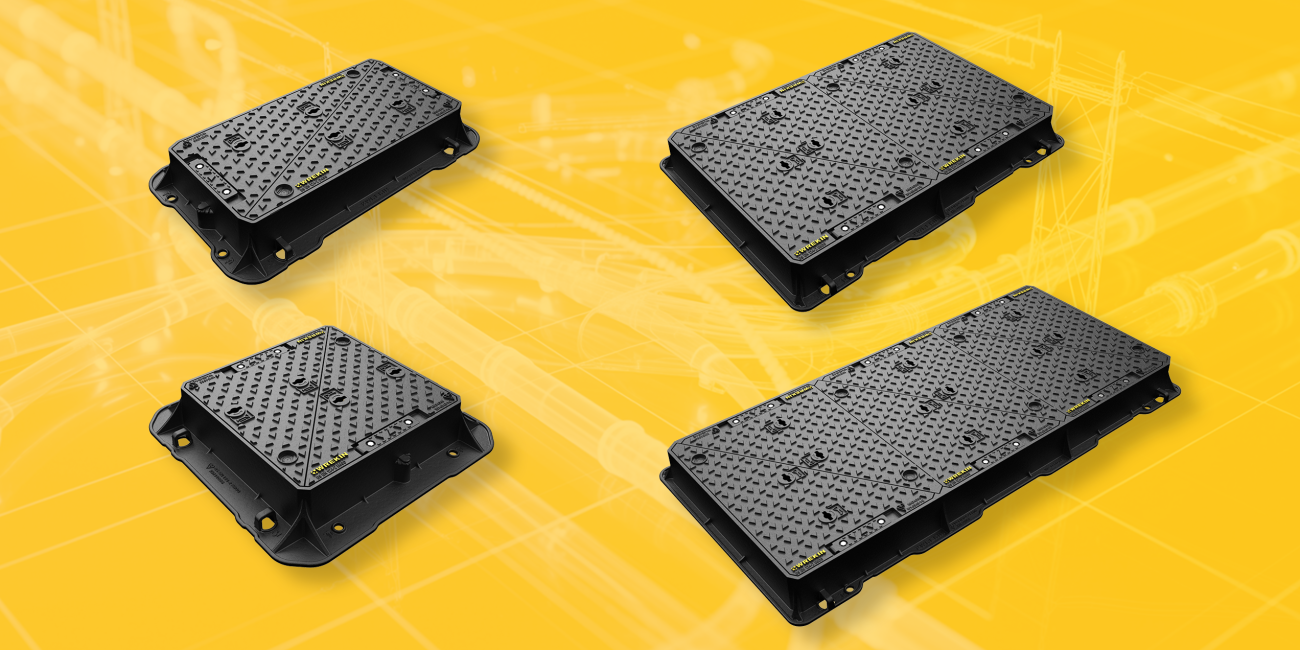

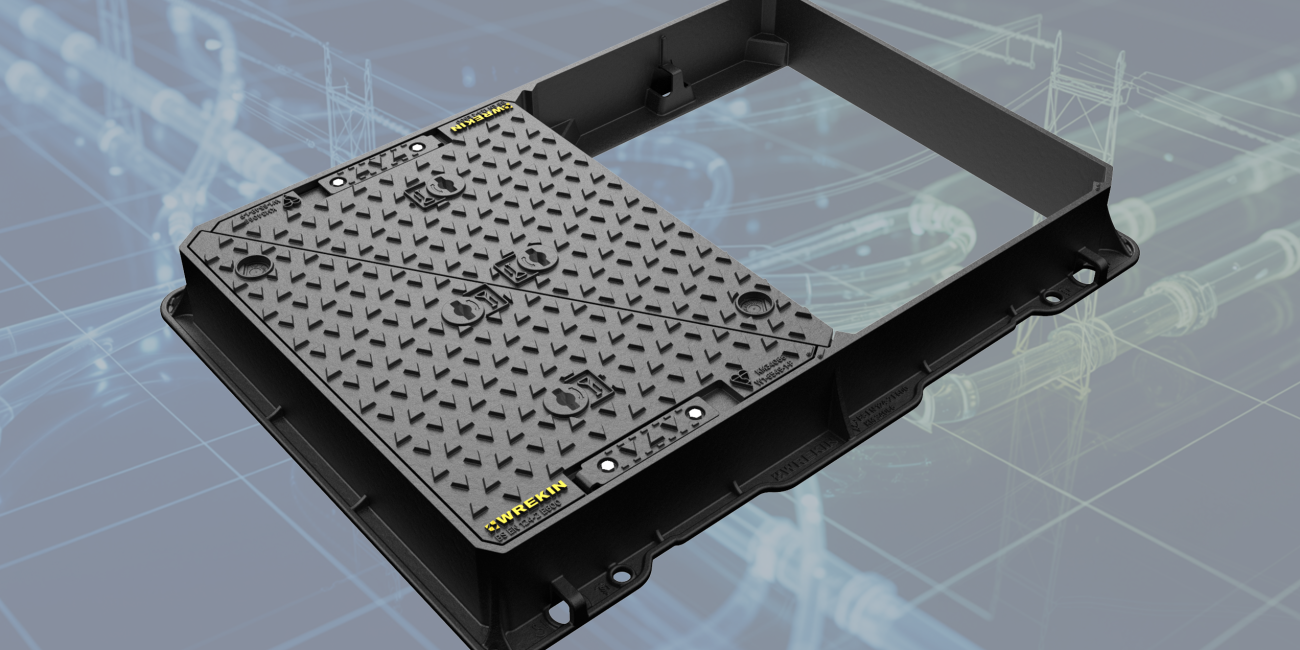

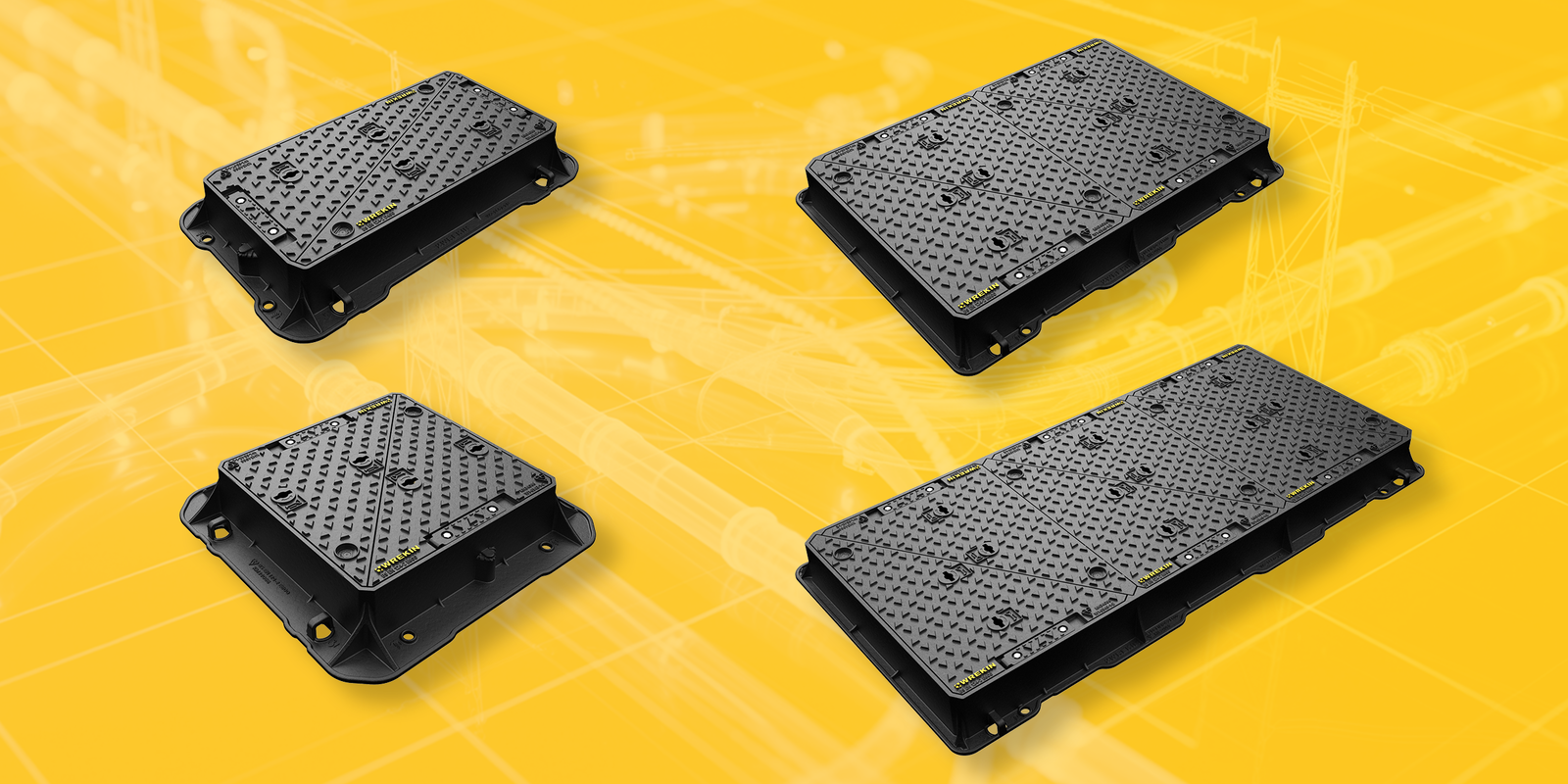

Square and rectangular manhole covers

Available options and accessoriesOptions

Accessories

Pulse 7-year warrantyWhen installed with either Wrekin UniPak® rapid-set polymer resin bedding mortar, or flowable, CD 534 compliant bedding mortar, the Pulse range is available with a 7-year product warranty*. Due to its unique design and overwhelming success in the local authority and utilities sector, Pulse is the proven choice for durability and longevity for highway ironwork installations. View further warranty information * Subject to terms and conditions Pulse gallery

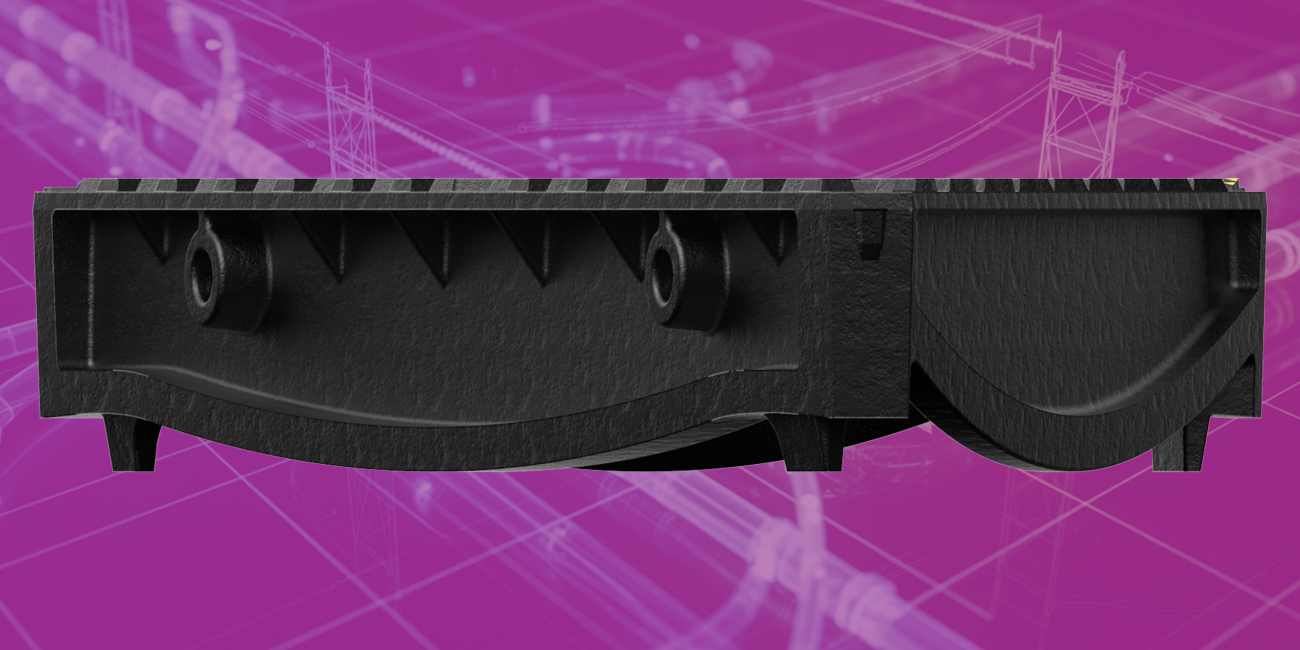

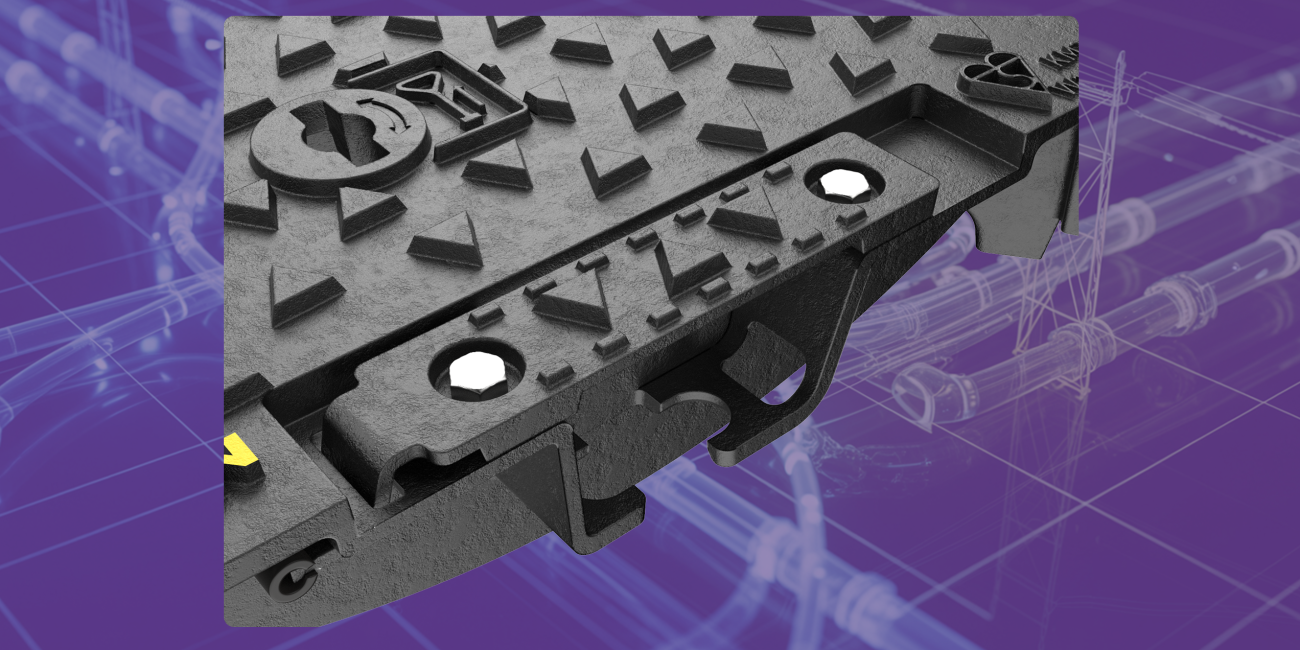

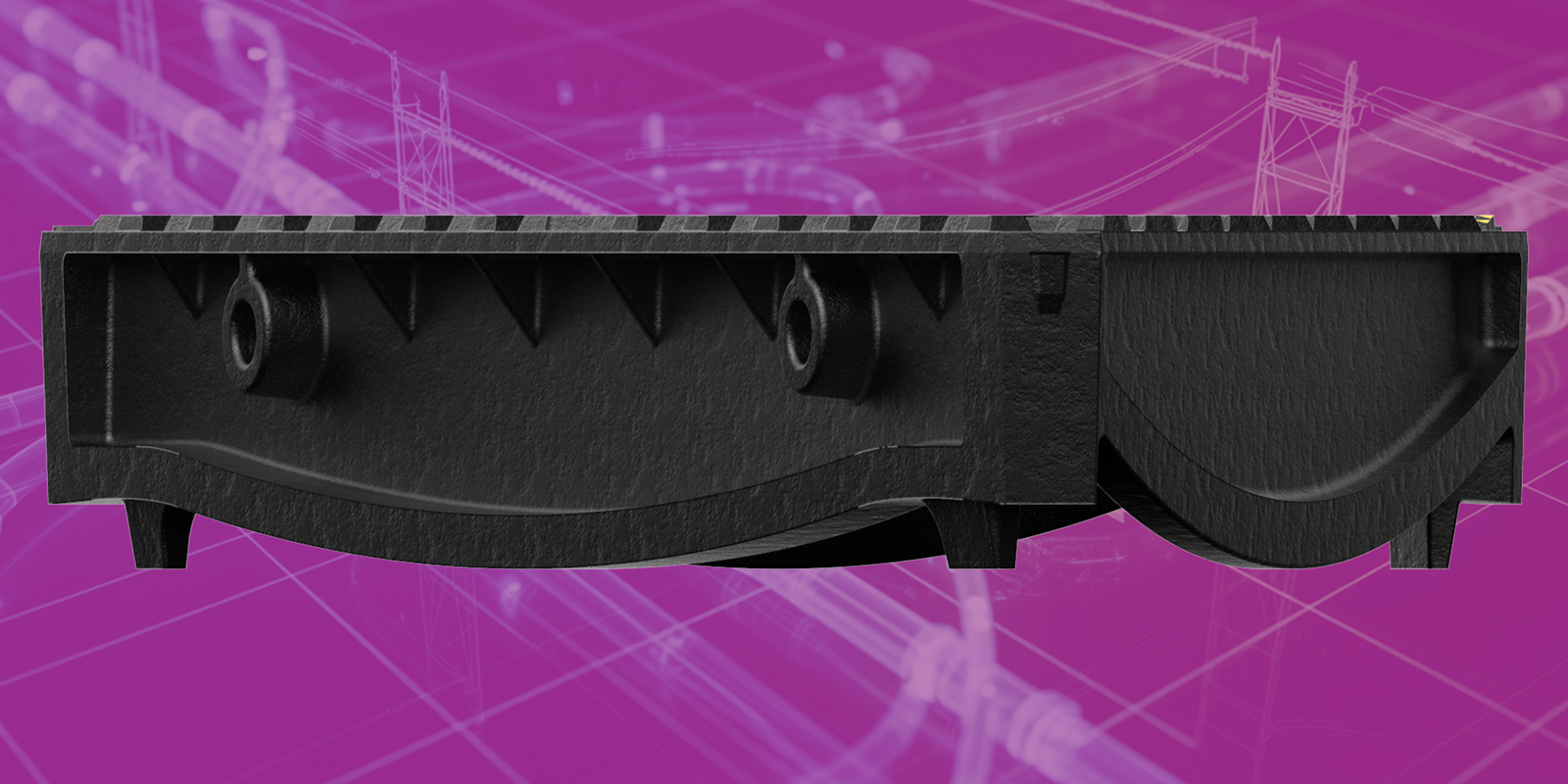

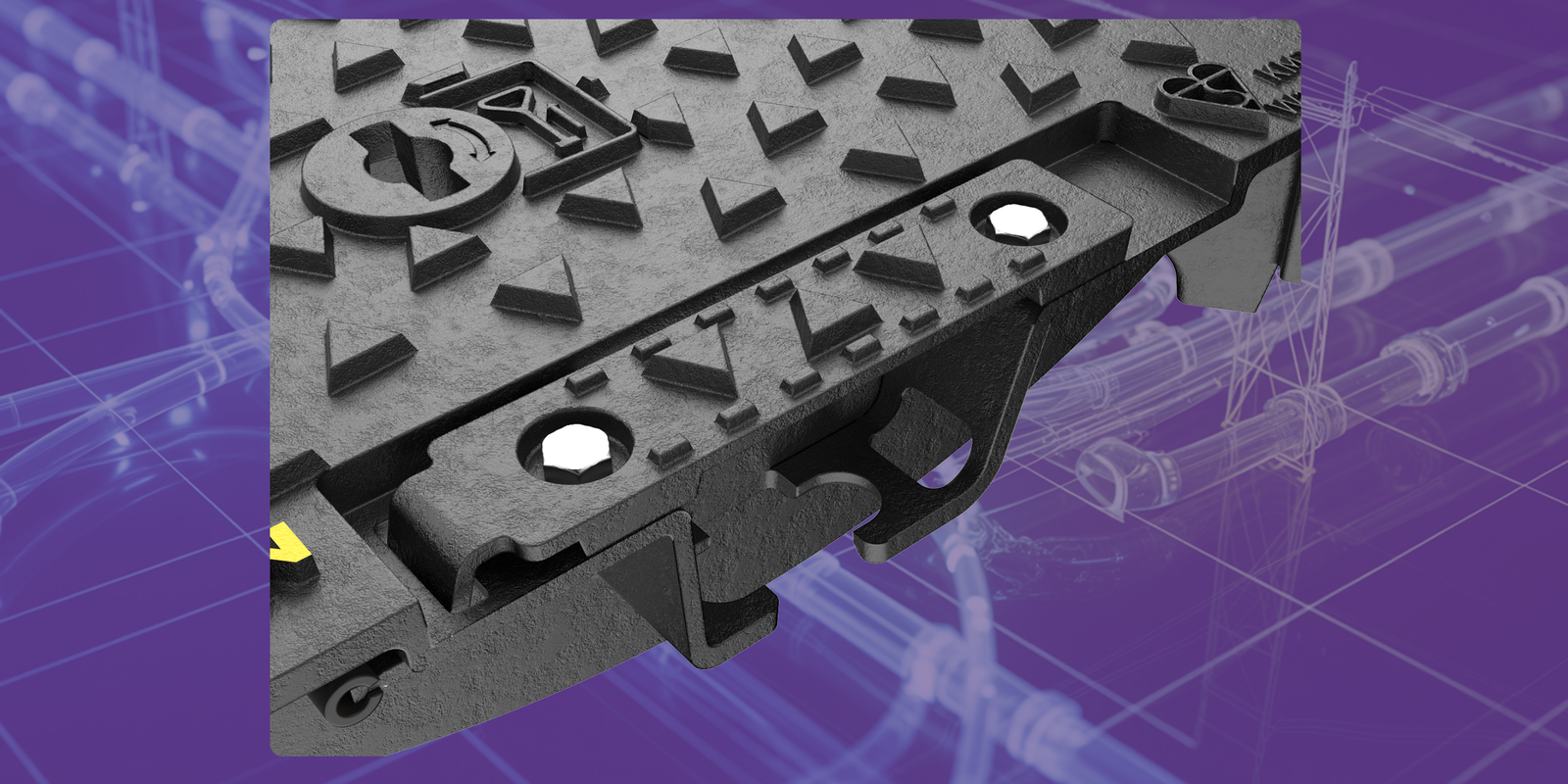

Engineered to protect the chamber and the bedding beneathInverted T-flange frame for balanced, long-term stabilityAt the core of Pulse’s performance is its inverted T-flange frame, a new generation of frame design developed through extensive finite-element analysis, field trials and live-traffic evaluations across UK networks. The profile provides continuous support around the frame edge, reducing deflection and distributing loads evenly around the whole frame into the bedding mortar and chamber structure. This geometry balances stresses across the frame. Preventing the outer edge lifting that can crack bedding mortar and the inner edge drop that can damage chamber walls. Independent testing confirmed up to 78% reduction in peak bedding stress and around 13% less deflection compared with welded-frame designs. †Only available on Carriageway 2 and 3 variants.

Strength and stability where it’s needed mostI-beam reinforced covers for superior rigidityThe Pulse cover structure features universal beam reinforcement (otherwise known as I-beams). Engineered to deliver exceptional rigidity and stability under repeated wheel loading. This design strengthens the cover without unnecessary weight, helping it resist flexing and seat wear that can develop over time. By controlling deflection, the I-beam structure ensures consistent load transfer between the cover and frame, maintaining a rock-free seating and reducing long-term fatigue. The result is a robust, stable assembly that protects the integrity of the chamber below and extends service life, even in the most demanding carriageway environments.

Secure by design, protected for performanceInboard locking system for lasting protectionPulse features a robust inboard locking system housed safely within the frame, which is designed to accept a padlock. It offers long-term security and reduces vulnerability to damage or interference. By protecting the locking mechanism from exposure to traffic and environmental wear, the system maintains consistent performance throughout its service life. This fully integrated design ensures the lock remains secure, reliable and easy to operate, even in demanding carriageway conditions. For network operators and asset owners, it provides added confidence that critical infrastructure remains protected against unauthorised access and premature wear, without compromising installation efficiency or ease of maintenance.

Engineered for safer, faster handling on siteIntegrated frame lifting points for safer installationsPulse includes a purpose-designed mechanical lifting points built directly into the frame, enabling safe, balanced and controlled handling during installation. This integrated feature removes the need for external lifting attachments, reducing manual handling risks and helping installers position the frame accurately and efficiently. By providing a secure lifting location, the system ensures even weight distribution, minimises strain on the frame, and supports precise alignment with the prepared bedding. The result is a faster, safer and more consistent installation process that protects both the product and the people handling it on site.

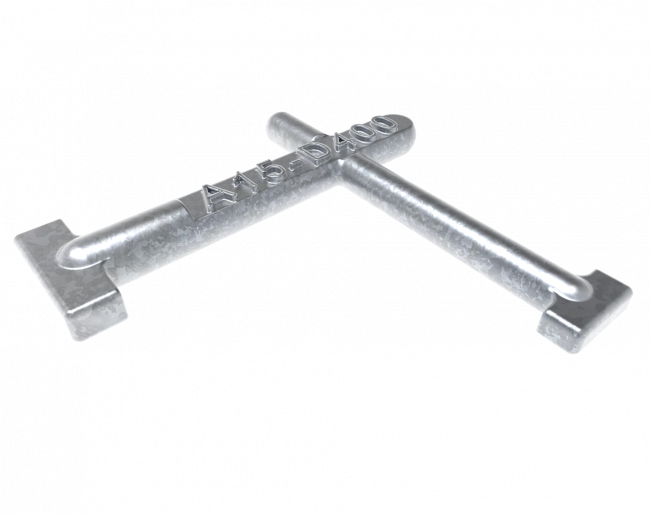

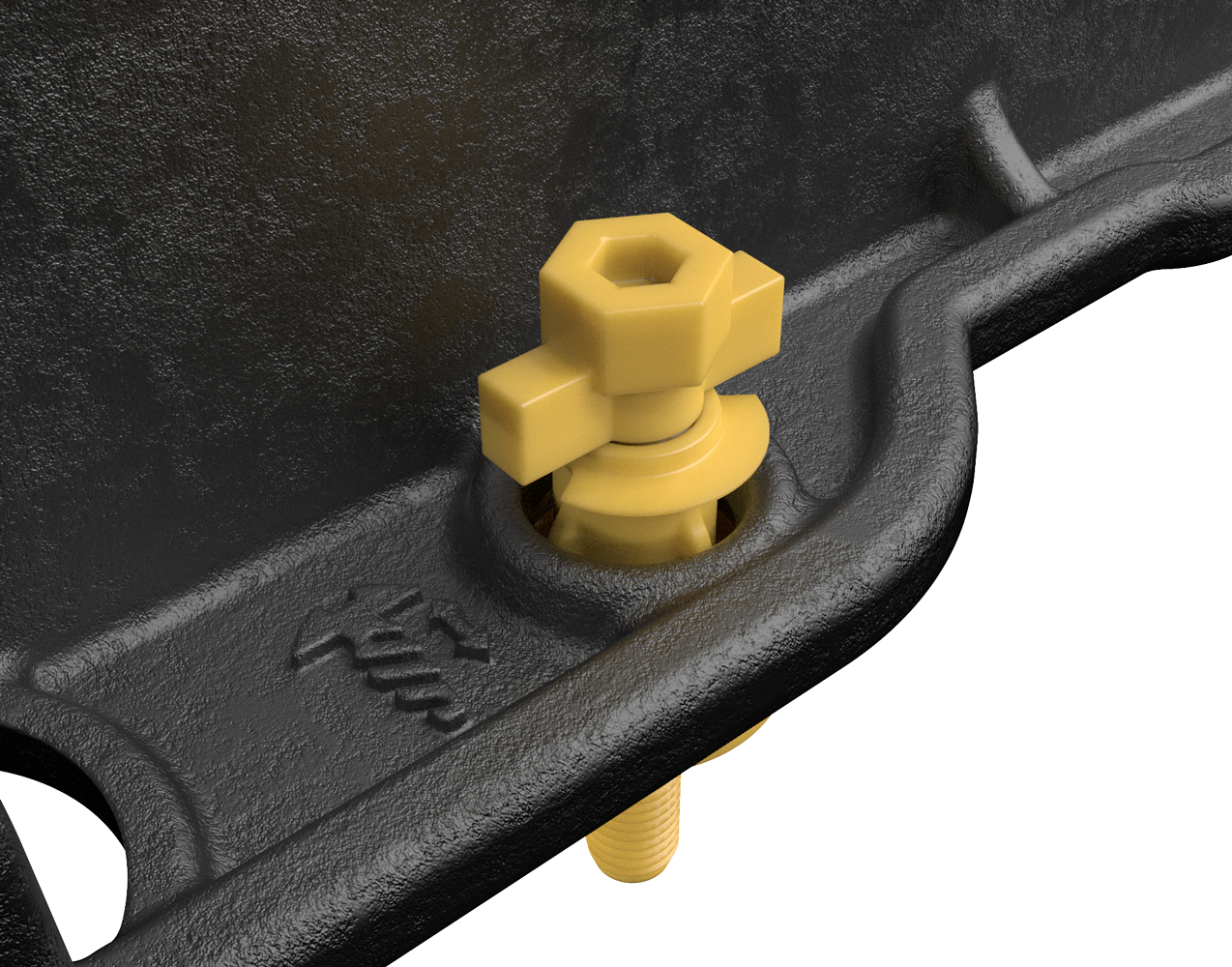

Designed with practicality and safety in mindSmart details that make a real differencePulse has been carefully designed to make installation and maintenance safer and more efficient. Every feature has a purpose, from clearly marked details to indexing points that support quick, accurate installations and maintenance. Distinctive feature markings and iconography make product type, loading and orientation easy to identify, while the dedicated ID bolt and RFID location support asset tracking and network management. The safety keyway prevents accidental disengagement during lifting, improving on-site safety and usability. For installers, the ScrewLift location in the flange supports fast, precise alignment during installation. While the rounded flange edges and multiple frame gussets enhance the strength and longevity of the installation. Together, these practical refinements help reduce risk, improve accuracy and ensure a consistent, professional finish every time. Precision levelling for stronger, faster installationsCompatible with ScrewLift rapid frame levelling systemPulse is fully compatible with our ScrewLift rapid frame levelling system, developed to make manhole frame installation faster, safer and more precise. The ScrewLift mechanism allows installers to accurately adjust frame height and alignment by hand, with an Allen key or socket, ensuring the frame sits perfectly level with the surrounding surface. By controlling the correct bedding thickness, ScrewLift helps prevent voids, bridging and uneven load transfer, supporting CD 534-compliant, long-life installations. It works with all bedding materials, including our UniPak rapid-set polyester resin mortar and flowable mortars such as Instarmac Envirobed® CD 534. ScrewLift™ UniPak®

Every detail engineered for real-world performancePulse is packed with intelligent design features, each created to make installation easier, extend service life and deliver long-term value. From build quality to sustainability, every aspect has been considered to reduce whole-life costs, improve reliability and support the networks that keep our world connected.

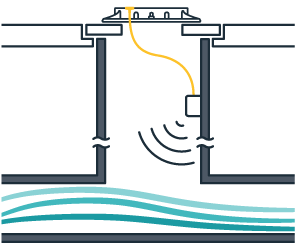

Only with WrekinRetrofittable antenna optionsUnite* and Highway access covers are the only ranges on the UK market to include provisions for communications equipment, such as antennas, to be installed within the cover.

The ID bolt provision can be used for antennas, allowing communications equipment, such as water meter monitoring, to be installed within a chamber beneath a cover while providing a strong signal above ground without the need to dig or adjust the surrounding road surface. Saving significant time, effort and money while minimising disruption. * references ending /KUE Pulse accessories

Contact usWhether you are looking for live project support, or are in the initial stages of specification, we are always on hand and happy to help. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||