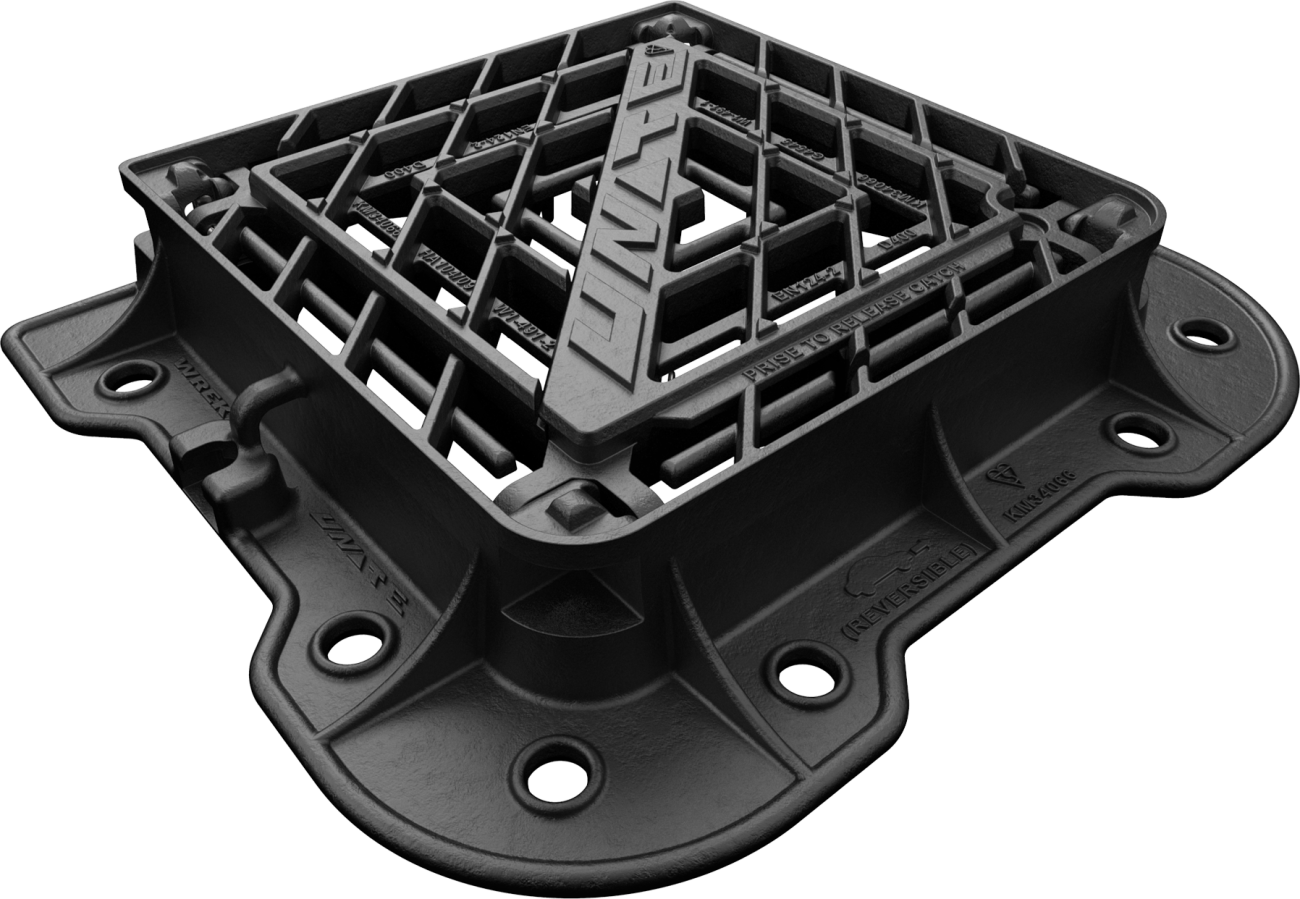

DGHT0D4/4545/KUUnite D400 3 flange gully grate clear opening 450mm x 450mm clear opening with 100mm frame depth

Features

SpecificationGeneral information

Standards, classes and groupings

Dimensions

EPD Data

Accessories

NotesThe D400 load capability of these Group 3 products also offers the benefit of making them suitable for exposure to Group 4 traffic types. Where 3-flange D400 Gully Grate assemblies are employed, we recommend that they are installed against a kerb, not in an open highway location. Fully compliant with the requirements of specification clause 6.2.47 of Cycle Infrastructure Design Local Transport Note 1/20.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||