|

Geoworks has replaced Wrekin Geosynthetics, our geosynthetics products are available at Geoworks.eco Throughout our 40 year history of being a leading UK designer, manufacturer and supplier of specialist products for the civil engineering industry, we have always made strides to consciously improve our ESG performance. In our Environmental, Social and Governance (ESG) report, we aim to be transparent with our customers and partners about the ways we are monitoring and improving our impact on the world. We are committed to working towards minimising the environmental impact of all our activities, from developing products that increase whole-life performance to increasing recycling and reducing waste wherever we can. We will also continue to improve our social impact and governance performance.

The Sea Starts HereRaising Awareness Through Everyday InfrastructureWe’ve taken a simple but powerful step by adding the message “The Sea Starts Here” to many of our ductile iron gully gratings. It’s a visual nudge at street level, reminding everyone that water, and whatever it carries, flows from our roads directly into natural watercourses and, ultimately, the sea. This subtle intervention aims to engage communities and encourage small but meaningful behavioural changes, like disposing of waste properly and reducing pollutants entering the drainage network. Collaborating for Cleaner OutcomesThis initiative is part of a broader collaborative effort to support water quality improvements. We’ve aligned with Canal & River Trust to make sure our products and messages are part of wider sustainability and education campaigns. By putting our name behind the cause and embedding the message into the very fabric of our streets, we’re not only offering technical solutions, we’re helping to shape a culture of environmental responsibility across the supply chain.

COLLABORATING FOR CLEANER OUTCOMESThis initiative is part of a broader collaborative effort to support water quality improvements. We’ve aligned with local authorities and environmental groups to make sure our products and messages are part of wider sustainability and education campaigns. By putting our name behind the cause and embedding the message into the very fabric of our streets, we’re not only offering technical solutions, we’re helping to shape a culture of environmental responsibility across the supply chain.

Fully committed to a sustainable futureWe pledge to constantly monitor our continued sustainability improvements through the setting of quantifiable objectives and targets on an annual basis. We have introduced a documented environmental management system using BS EN ISO 14001:2004 as the framework to evaluate and improve our environmental performance. We will comply with relevant environmental legislation and endeavour to stay ahead of proposed legislation by implementing the best practices of the industry wherever this is practical. In all of these areas, management will take the lead in providing the commitment and focus to empower local teams to make the maximum contribution to improving environmental performance. This includes the provision of the relevant information, training and resources necessary to enable all employees whose work has a potential environmental impact to make a maximum contribution to achieving our business objectives and targets. A crucial time to take actionHere are just some of the ways we are leading the field in helping to ensure a more sustainable future:

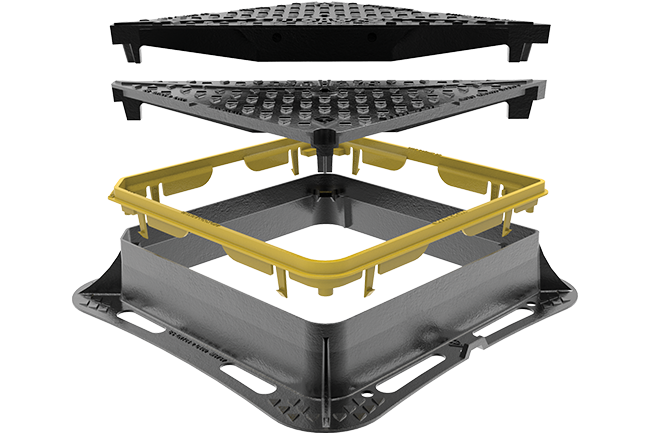

One of our most successful partnerships is with Thames Water, which was experiencing problems with the lifespan of its manhole covers on some of London’s busiest and most demanding routes. With approximately 1.2 million manhole covers across 67,000km of sewers, the company needed a solution that was easy to install and proven to last. We have now supplied more than 100,000 units to the company without one recorded failure for more than 10 years. Our industry-leading ductile products are designed to use as little material as possible without impacting on their strength. The benefits of this can mean a reduction in CO2 emissions when shipping - and allows for more of the products to be shipped together. Through clever engineering we create strength in our access covers which provides rigidity and longevity. Unite range is the very definition of sustainability. A decade in the making and has been in service on the UK’s highways for over 18 years with more than 500,000 installations and zero recorded failures. Unite when used with our rapid curing UniPak mortar system comes with a 10-year guarantee, providing whole life cost savings. Unite has patented features that minimise the bedding pressure, which allows clients to simply ‘fit and forget’ – saving them a lot of time and money over the years by not having to dig up roads for repairs and replacements due to failing ironwork.

We take our responsibilities seriouslyAs a company, we work to continuously improve our health, safety and environmental performance, and to communicate with our stakeholders about our collective performance. We operate safely, profitably, with due care for future generations and work towards sustainable development. Wrekin works to support:

Our innovative manhole covers need only to be installed once - and raised with ClickLift - so there is no need for a client to do the same job twice

Armadillo ensures manhole covers and gully grates can be installed once and protected throughout a new development, thereby minimising waste

UniPak mortar cures rapidly, within an hour, meaning roads do not need to be closed for days - reducing the impact of queuing traffic. A manhole cover can be replaced in a few hours and the road reopened

Many of our products are manufactured from fully recyclable ductile iron and steel

Contact usWhether you are looking for live project support, or are in the initial stages of specification, we are always on hand and happy to help. More about us

|