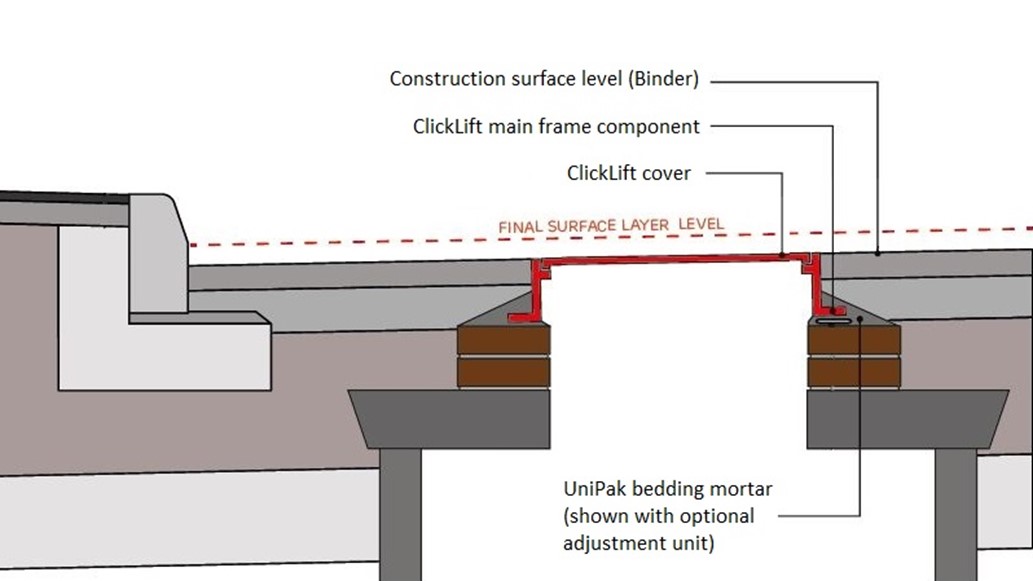

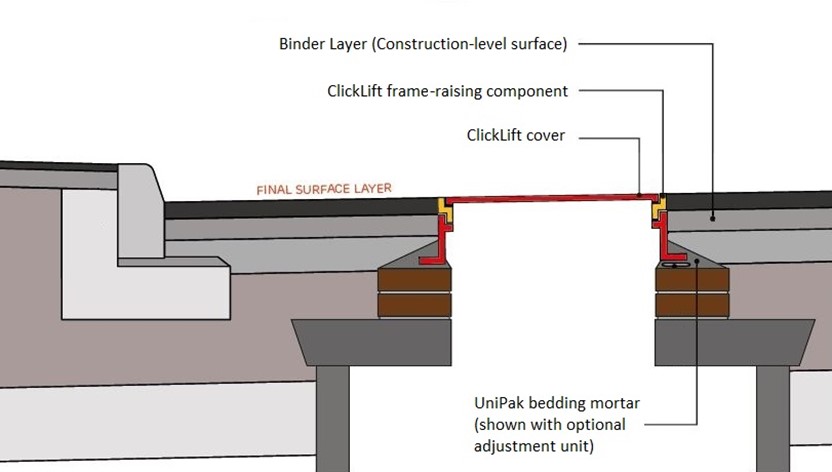

Manhole cover with Clicklift installation guideIntroduction to this guideThis installation guide is for cast ductile iron BS EN 124 access cover assemblies used in new build applications when using a permanent 1st fix (at reduced levels) to concrete slab or engineering brick-top chambers. General note: This installation method anticipates the use of Wrekin Clicklift assemblies for raising of ironwork from an initial reduced level installation position (See Installation Guide No.2 for raising of ironwork from a reduced level but not involving the use of ClickLift assemblies) The following installation guidance document refers to permanent, sequential-installation of new Wrekin BS EN 124 ClickLift ironwork products and materials, initially at reduced levels flush with the surrounding construction-phase [Binder] surfacing, followed at a later date by fitment of the final ClickLift component flush with finish surfacing levels. The ClickLift apparatus is therefore supplied in two separate parts, comprising: A main frame and cover assembly (as a manhole cover and frame) and a separate frame raising component. The installation’s permanent construction is intended to comply, as appropriate, with; DMRB CD534 (or HA104/09) MCHW, SfA (The Code), UK Water Industry CP373a/P8669 WRc Inspectors Guide to Ironwork, RSTA CoP and/or FACTA Standards. In the case of any conflicting requirements, the Standard or Client Specification relevant to the product material and size will prevail. This installation guide assumes that the new chamber support structure is of adequate condition and strength to suit the intended load class of the ironwork being installed. All site operatives responsible for installation shall have experience of or familiarise themselves with the type of products & materials being installed and shall ensure the necessary PPE is used. Where any uncertainty exists, consult Wrekin for advice. (01543 440440 or www.wrekinproducts.com). In all cases, precautions should be taken to prevent operatives from deliberately or accidentally exchanging cover/grating elements between product assemblies. Similarly, covers or gratings removed from their frames should always be placed back in the same orientation in their original frames in order to prevent mal operation during trafficking. Where the use of a bedding mortar is referred to, it is intended to reflect the use of a high-performance, Polyester-Resin material used as the primary, frame-flange encapsulation and bedding mortar. E.g. Wrekin Unipak bedding mortar. Where the use of ‘adjustment units’ are referred to, it is intended to reflect the use of MCHW-compliant, proprietary, high-performance, foundation-sympathetic components. E.g. Wrekin’s UniForm adjustment units. When dealing with heavy ironwork, it is recommended operatives use mechanical lifting devices wherever possible in order to minimise manual handling. To ensure large cover and frame assemblies are not damaged or over-stressed during lifting, use all the frame lifting features provided, equally. Preparation of the new chamber top for permanent ironwork fitmentIn order to maximise the performance of the installation, ensure the following guidance is followed:

Bedding depth requirements (for construction phase and service use)Based on the anticipated construction phase / finished surfacing level and taking account of the nature of ClickLift assembly options (main frame depth and frame raising section depth), calculate the ironwork’s mortar bedding depth requirements using the following as a guide:

N.B.1: Ensure that the under-frame mortar bedding depth will exceed 10mm at all locations. N.B.2: Ensure sufficient volume of mortar is available to complete the bedding and achieve the required bedding thickness and a 10mm enveloping of the frame flange surface. As a guide, a typical 1x25Kg tub of bedding material will provide up to 15mm bedding depth for a typical 600x600mm Clear Area access cover. Permanent bedding mortar application and frame-alignment using the Tamping techniqueThis procedure assumes that the bedding mortar used is for permanent fixing of the ClickLift main frame in readiness for later fitment of the ClickLift raising section.

Frame Tamping is the expected common method of ironwork Frame alignment with the anticipated (or existing) surrounding road surface and in order to ensure its effectiveness, particular attention is drawn to the following:

Alternative Clicklift main frame bedding method(for use at elevated temperatures where short mortar working time prevents conventional frame tamping) Where the bedding mortar working time is too short to allow mortar placement and frame alignment using a conventional ‘tamping’ technique, alternative installation techniques may be used to effect frame alignment.

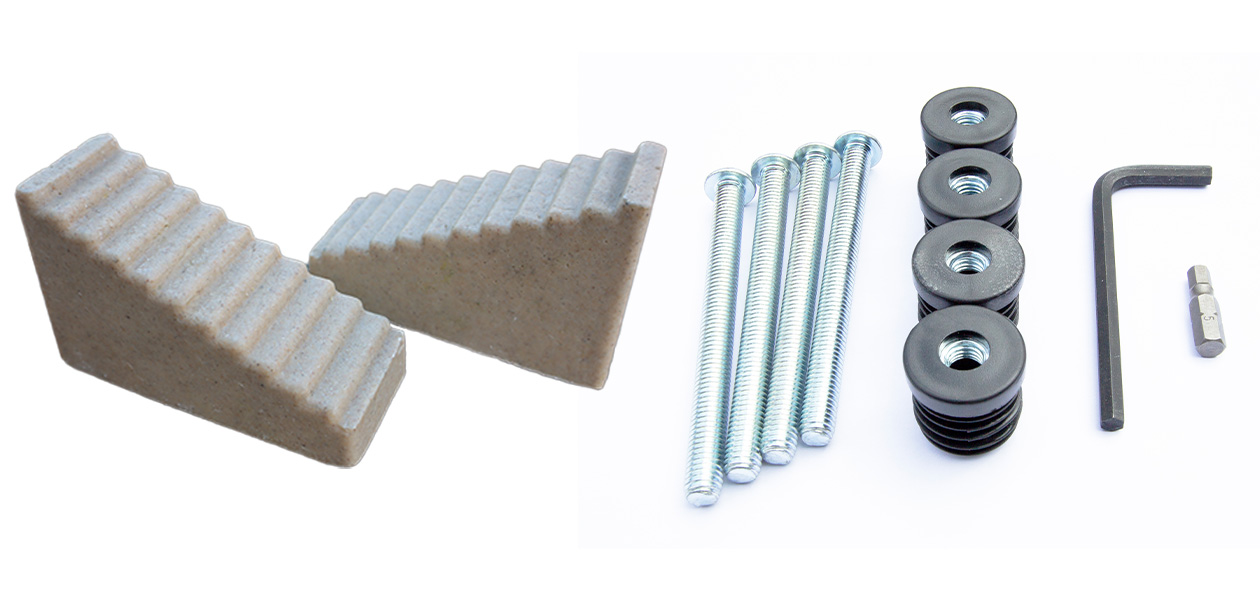

Examples of alternative techniques include: UniForm Wedges or ScrewLift adjustment accessories, where these may be used to effect frame-levelling in lieu of frame tamping. Either method may be used, followed by application of a Wrekin-approved flowable bedding mortar (which will require a temporary dam to be formed around the chamber top) or manual application of UniPak mortar under and over the frame flange (enveloping). Where manual enveloping of the frame is carried out (achieving 10mm minimum depth underneath and on top of the flange), ensure that all of the applied mortar is compacted and its resulting surface is textured to provide a key to subsequent reinstatement materials. N.B.3: Where UniForm Wedges or ScrewLift accessories are employed for frame levelling, they may to be left in-situ with the surrounding bedding mortar. Additional Frame FixingsIf frame fixing anchors are to be used in conjunction with a bedding mortar as a means of additional frame retention to the chamber top, drilling or hole-forming to receive anchors should only occur when the bedding mortar has fully cured. N.B.4: Ensure any chamber fixing location and anchor type is appropriate for the expected loads. N.B.5: Anchor fasteners are not supplied with Wrekin Products’ ironwork, as standard. Construction-phase surfacing (e.g. Binder course)When the Clicklift main frame installation has been completed and its bedding materials have cured. The construction-phase surfacing may be applied, which should align flush (within +/-5mm) with the top of the ironwork in order to deter damage by construction traffic.

N.B.6: It is vital that when applying any surfacing courses, the ironwork is not disturbed or impacted, particularly where mechanical compaction equipment is employed, as this can damage the newly-laid bedding materials. Care should also be taken to remove all surfacing aggregates from the surface of the manhole cover and frame before compacting/rolling the asphalt in order to prevent any likelihood of point loading from compaction equipment. Construction-phase ironwork protectionIn situations where the construction-phase installation is likely to become exposed to pre-service (construction-site) or other damaging traffic types, ensure that it is protected until its normal service use, by temporary employment of the following;

N.B.7: Trafficking of the installation must not occur until all reinstatement and surfacing materials have fully cured and any necessary protection is in place. N.B.8: Fitment of the ironwork flush with the surrounding road or pavement affords it some protection from construction traffic but may not prevent damage from the high point loads associated with these traffic types. Hence, consider the additional protection shown above. Preparations for finish surfacing and fitting of the ClickLift raising frame componentImmediately prior to application of the finish surfacing and where the in-situ ClickLift main frame is required to be raised to finish levels, the following procedure and guidance should be followed:

**N.B.9: As the ClickLift raising component requires some engagement with the outside top edge of the ironwork frame, it may be necessary to clear away surrounding surfacing coincident with the top edge of the frame in order for the ClickLift to fully contact its frame seats and activate its barbed retention ‘legs’. N.B.10: Ensure that the correct ClickLift raising component height (from the range of 30, 40, 50 & 60mm) is selected before fitting to the in-situ frame, as once fitted, it cannot be easily removed. N.B.11: The application of a cold joint sealer to the ClickLift vertical external face is particularly important if it’s located in a concrete surround, for thermal expansion reasons. Finish SurfacingWith the Clicklift ironwork now fully assembled and installed, the finish surfacing may be applied, taking care that the ironwork is not disturbed or impacted, particularly where mechanical compaction equipment is employed, as this can damage the ironwork and/or bedding materials. Care should be taken to remove all surfacing aggregates from the surface of the ClickLift frame before compacting/rolling the asphalt in order to prevent any likelihood of point loading from compaction equipment. Post-surfacing protectionIn situations where the finished installation is likely to become exposed to pre-service (construction site) or other damaging traffic types, ensure that it is protected until its normal service use by the temporary employment of one of the following;

N.B.12: Trafficking of the finished installation must not occur until the surfacing has fully cured and any necessary protection is in place. Aftercare and MaintenanceIn general, non-hinged ironwork products require little routine maintenance during their lifetime when exposed to their normal UK service environment, other than ensuring any lifting keyways are clear and, where desired, repainting of their trafficked surfaces. Exceptions to this include ironwork assemblies that incorporate; perishable, replaceable components. E.g. Seating gaskets in circular covers. It is, however, always good practice to clean the contact (seating) positions of covers and frames when access has been gained to their underlying chambers. For specific guidance on assessment of an installation’s condition, refer to the WRc Inspector’s Guide to Street Ironwork for the UK Water Industry CP373a/P8669.

N.B.13: In order to deter debris ingress into manhole cover lifting keyways (and to ensure Lifting Key fitment), Wrekin’s GritBlocker accessory may be used as a permanent fitment into same. Related pagesRelated products

| |||||||||||||||||||||||||||||||||||||