|

Geoworks has replaced Wrekin Geosynthetics, our geosynthetics products are available at Geoworks.eco

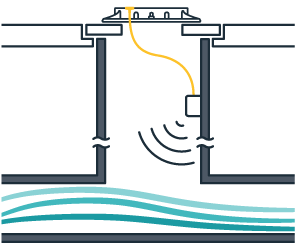

Only with WrekinRetrofittable antenna optionsUnite* and Highway access covers are the only ranges on the UK market to include provisions for communications equipment, such as antennas, to be installed within the cover.

The ID bolt provision can be used for antennas, allowing communications equipment, such as water meter monitoring, to be installed within a chamber beneath a cover while providing a strong signal above ground without the need to dig or adjust the surrounding road surface. Saving significant time, effort and money while minimising disruption. * references ending /KUE

Contact usWhether you are looking for live project support, or are in the initial stages of specification, we are always on hand and happy to help. |