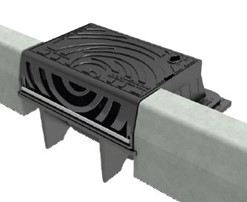

D400 Combined Kerb & Drainage unit with compatible Gully Chute ConnectorsTypical construction arrangement:This image illustrates the finished ironwork installation without road surfacing strata, but with a supporting mass concrete foundation in place.

Note: The above illustrates a typical BS EN124 Group 3 location where the complete ironwork assembly is integral to the kerb line. Construction considerationsIn order to decide the most appropriate construction sequence for a given site, the following factors should be taken into account:

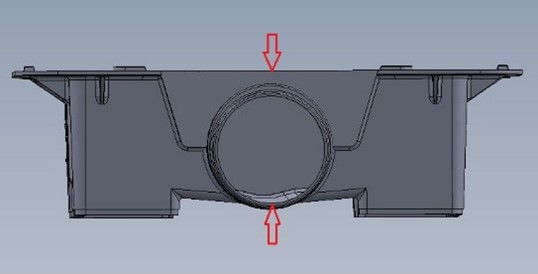

Note: Mass concrete supporting the Gully Chute Connector should ideally be a similar grade/strength and thickness as that used for bedding of the adjoining concrete kerbs.

Note: When fitting the pipework (etc.) to the spigot, clean and then coat the spigot with an elastomer-compatible lubricant to help prevent damage to the pipe fitting’s sealing element.

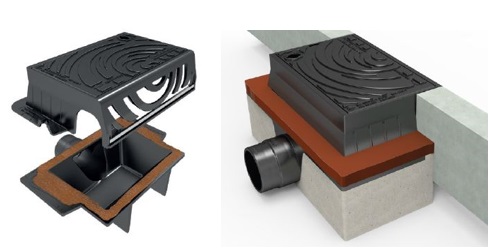

Post installation protectionIn situations where the finished ironwork installation is likely to become exposed to construction-type or other damaging traffic types prior to its intended service application, ensure that it is protected by the temporary fitment of one of the following:

Note: Trafficking of the finished installation must not occur until the bedding, structural materials and adjacent surfacing have fully cured and any necessary temporary, pre-service protection is in place. Aftercare and maintenanceIn general, cast iron products require little routine maintenance during their lifetime when exposed to their normal UK service environment. For further information, see Wrekin’s ‘Maintenance of BS EN124-2 Ironwork’ document. Related products

| |||||||||