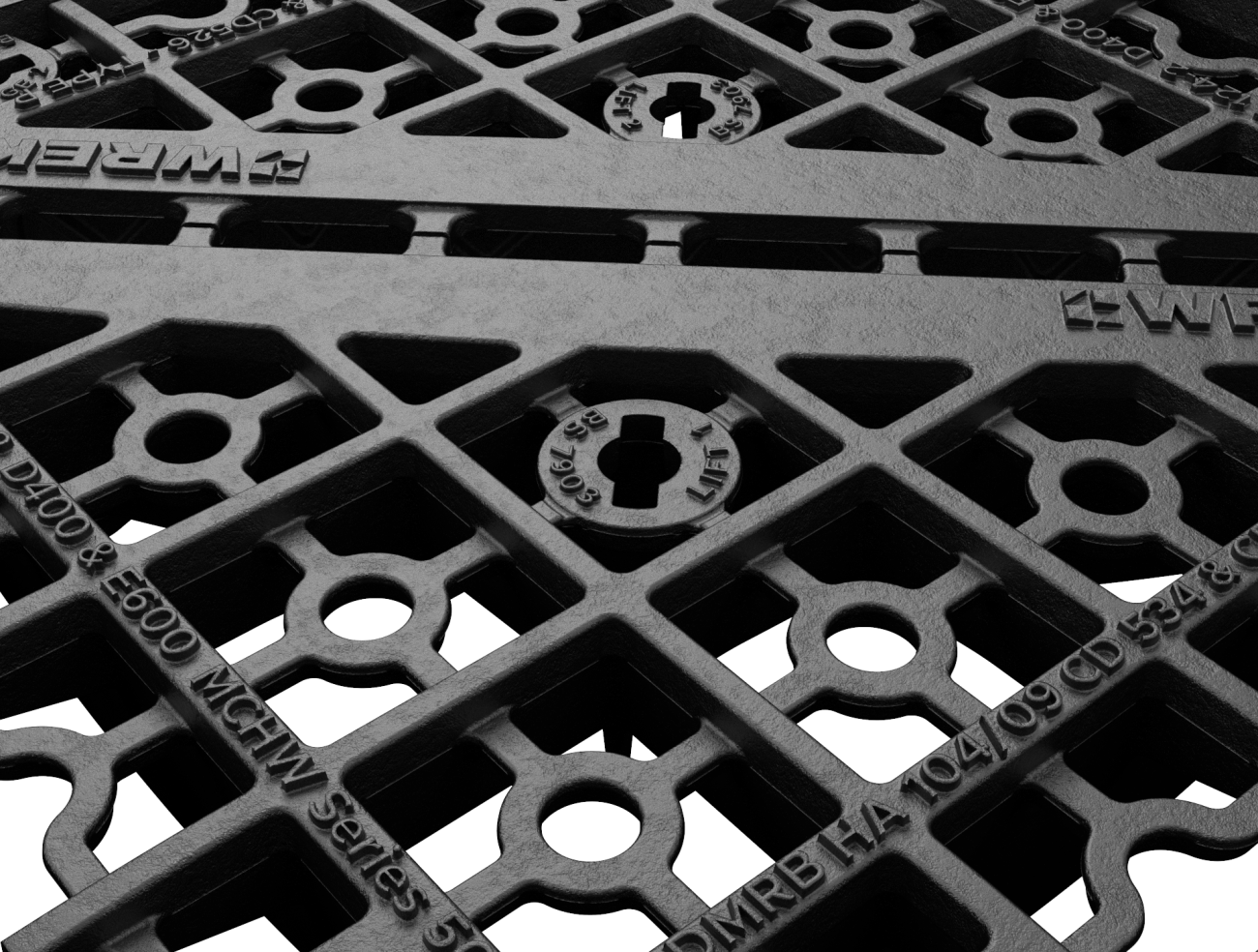

Smarter gully solutions can improve worker safety and maintenance efficiencyWith pressure mounting on local authorities to keep roads safe and traffic flowing amid rising maintenance demands, how can councils protect the wellbeing of the teams who maintain them? Paul Thompson, technical specification and sustainability manager at civil engineering solutions provider Wrekin, highlights approaches that improve worker safety and operational efficiency. Local authorities face increasing pressure to maintain safe and reliable road networks, and with only 48% of the local roads in England estimated to be in good structural condition, it is a problem that is not going away. Rising traffic volumes, ageing infrastructure and unpredictable weather create constant challenges for maintenance teams. One area that has a disproportionate impact on both workforce safety and operational efficiency is gully maintenance. Traditional gully grates are often very heavy, requiring two-person lifts and careful handling. Poorly maintained or displaced gullies can also lead to emergency repairs, increasing the number of times technicians must lift or move heavy covers, creating a cycle of physically demanding reactive work. Routine inspections can be labour-intensive, requiring crews to spend hours lifting, securing and checking grates rather than focusing on preventative measures. In many cases, inefficiencies in gully maintenance translate directly into increased risk of musculoskeletal injuries and workplace incidents for the highway technicians carrying out the work Health and safety considerations for maintenance crews are central to these challenges. Heavy gully grates are difficult to manoeuvre safely in confined spaces or in high traffic environments. Even minor slips or strains can lead to significant injury and lost working time. Local authorities must find ways to safeguard the wellbeing of roadside operatives while maintaining operational efficiency.

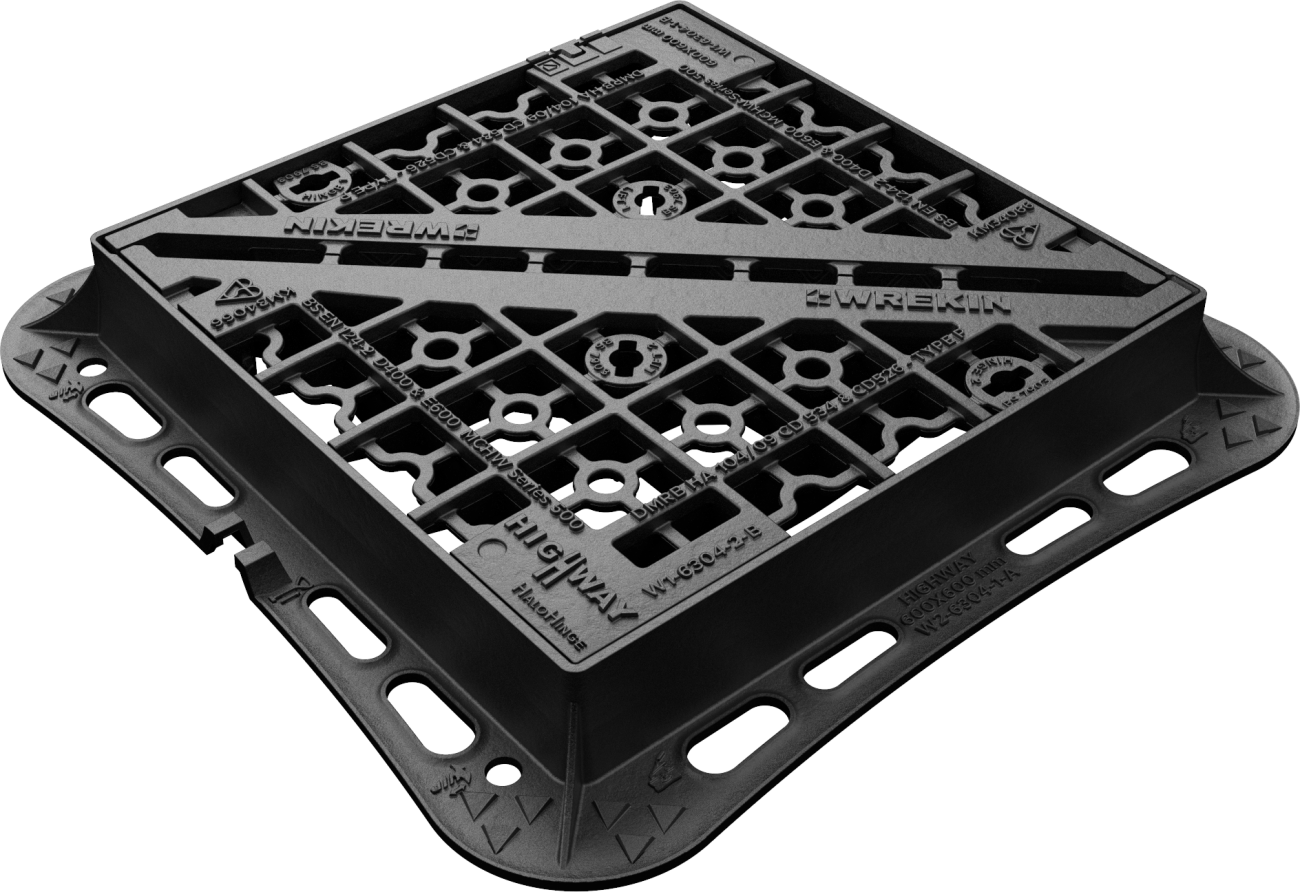

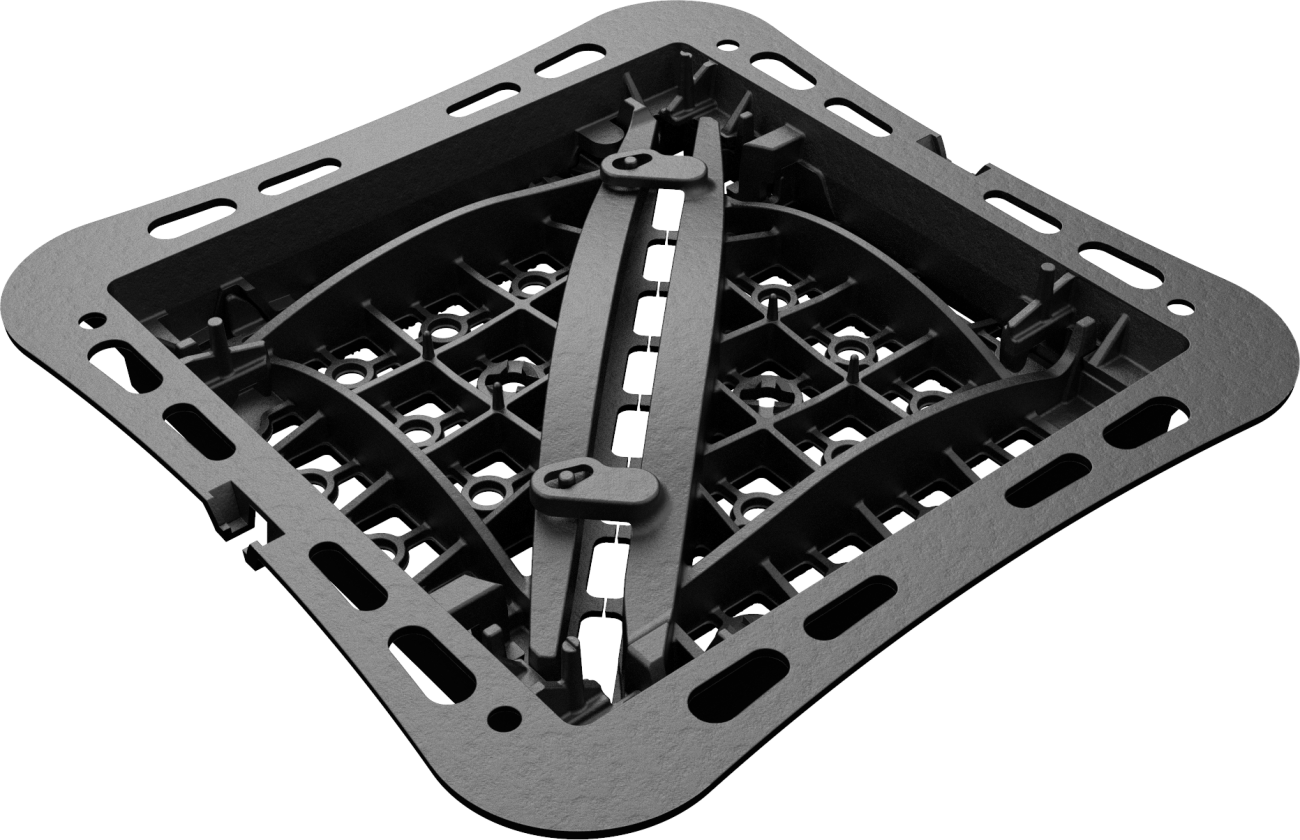

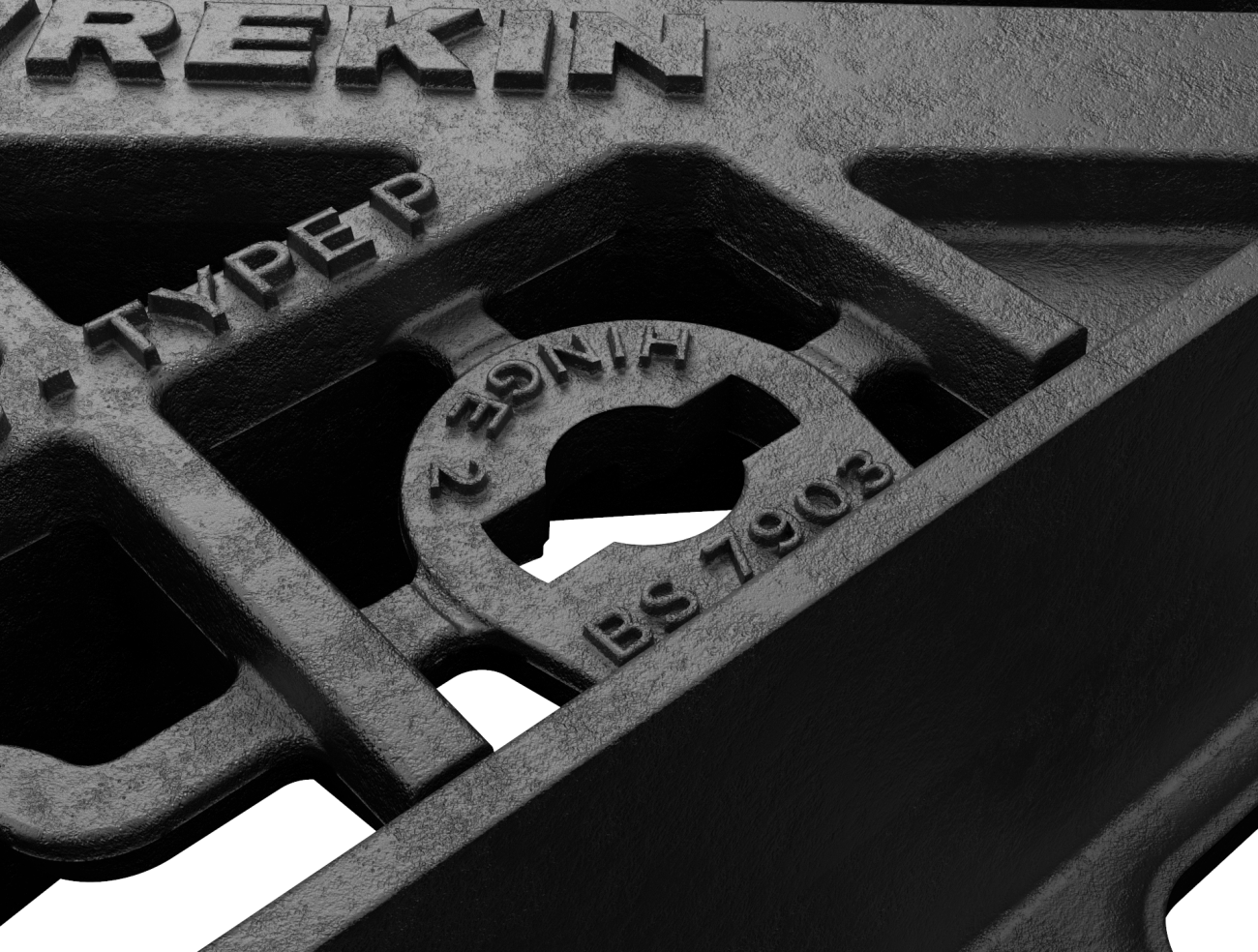

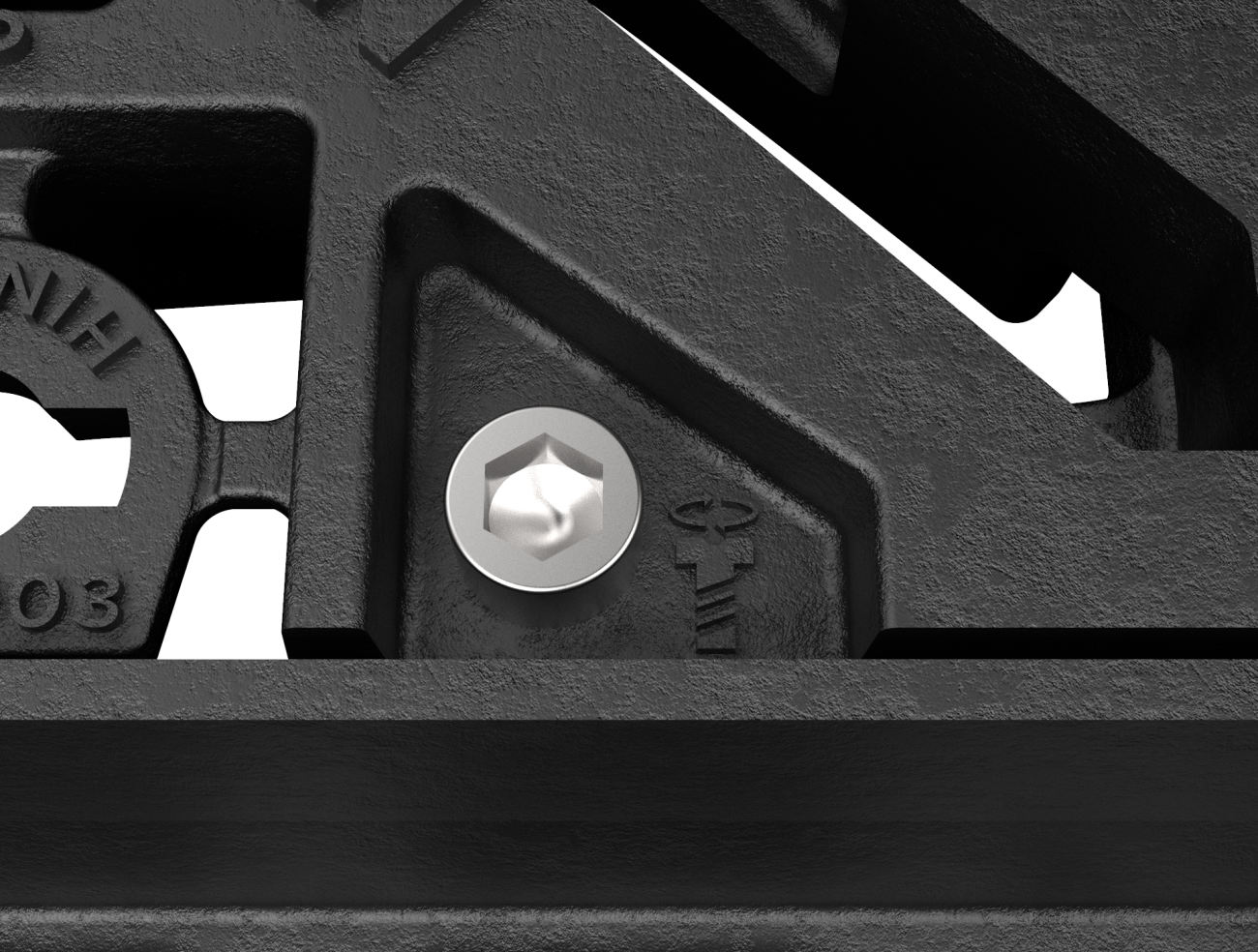

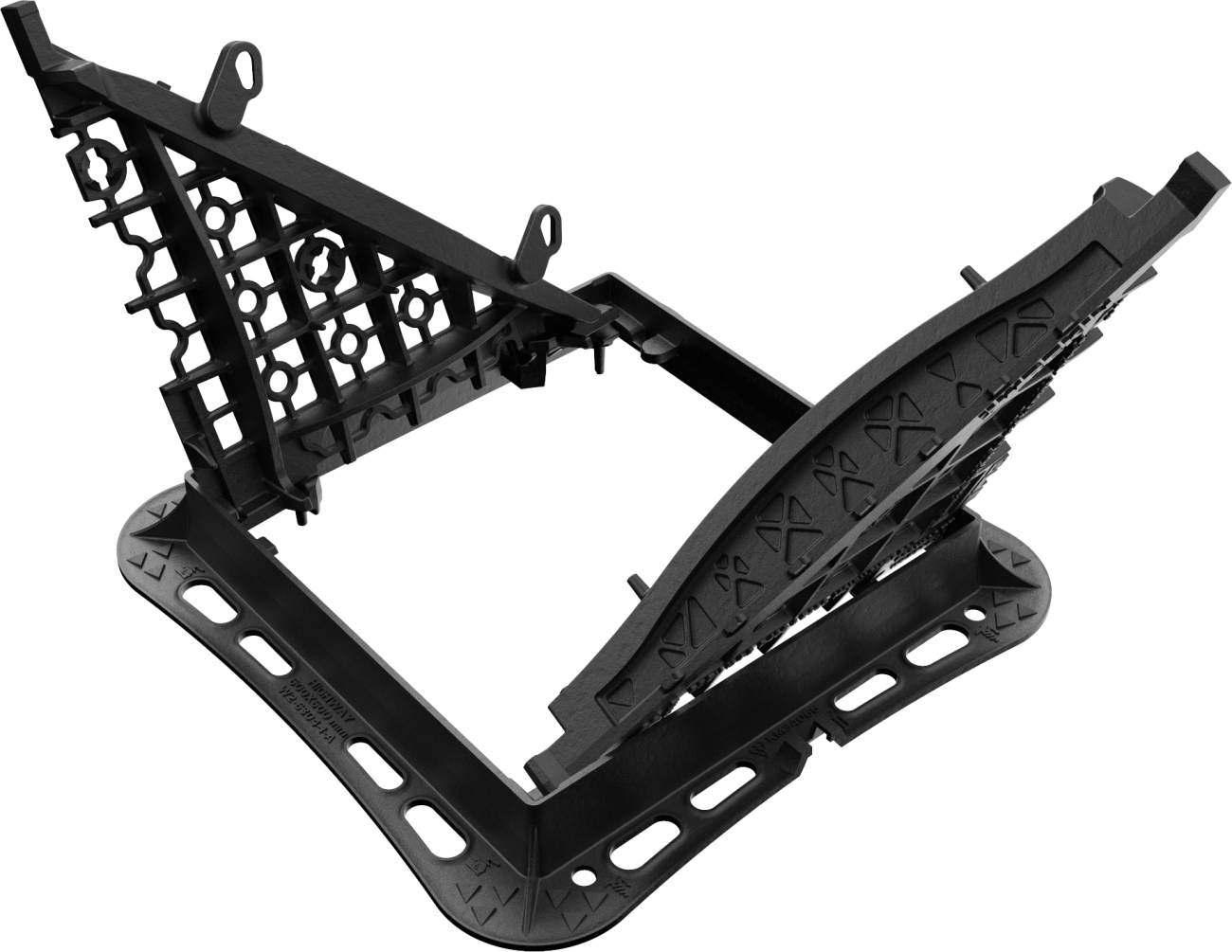

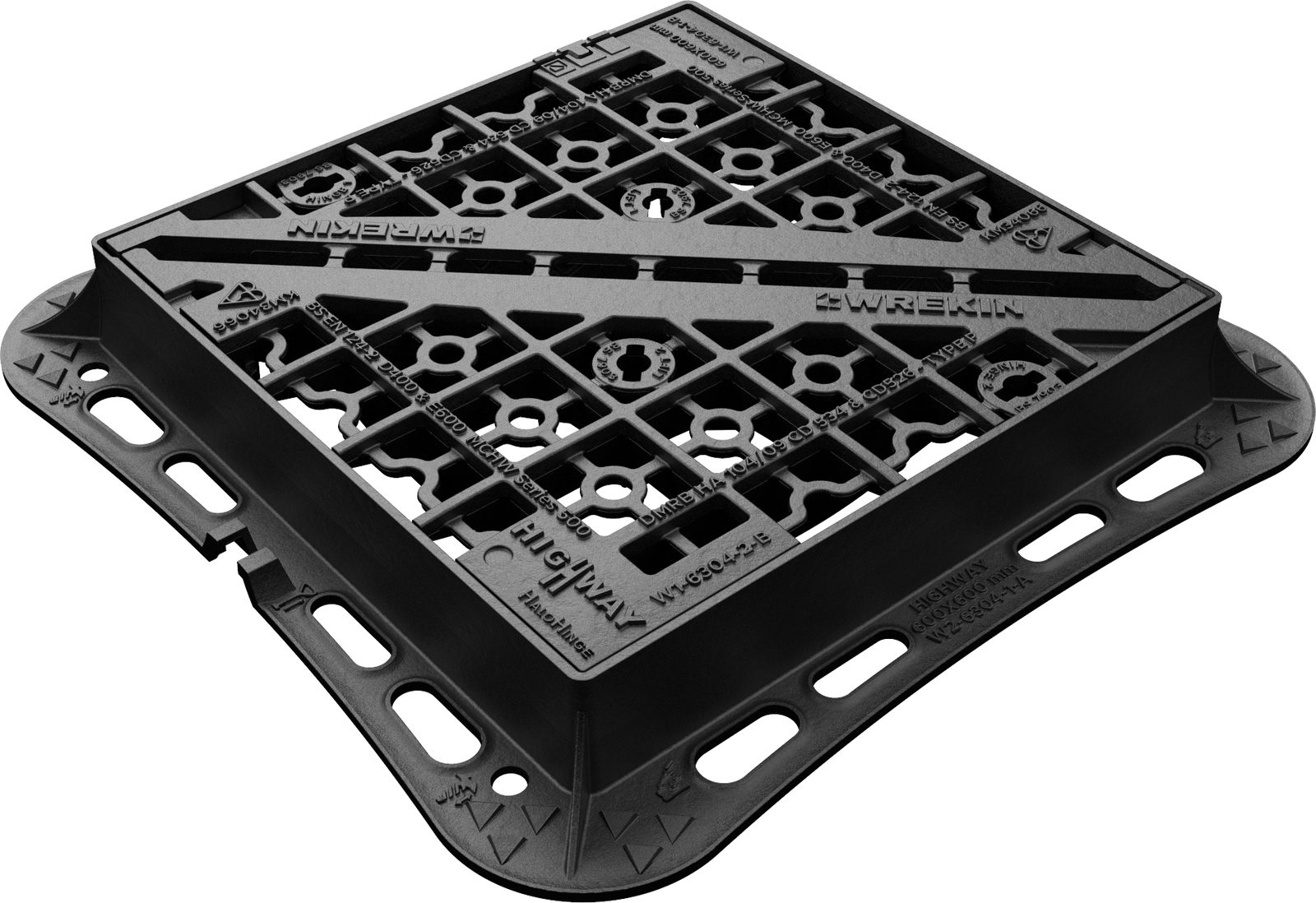

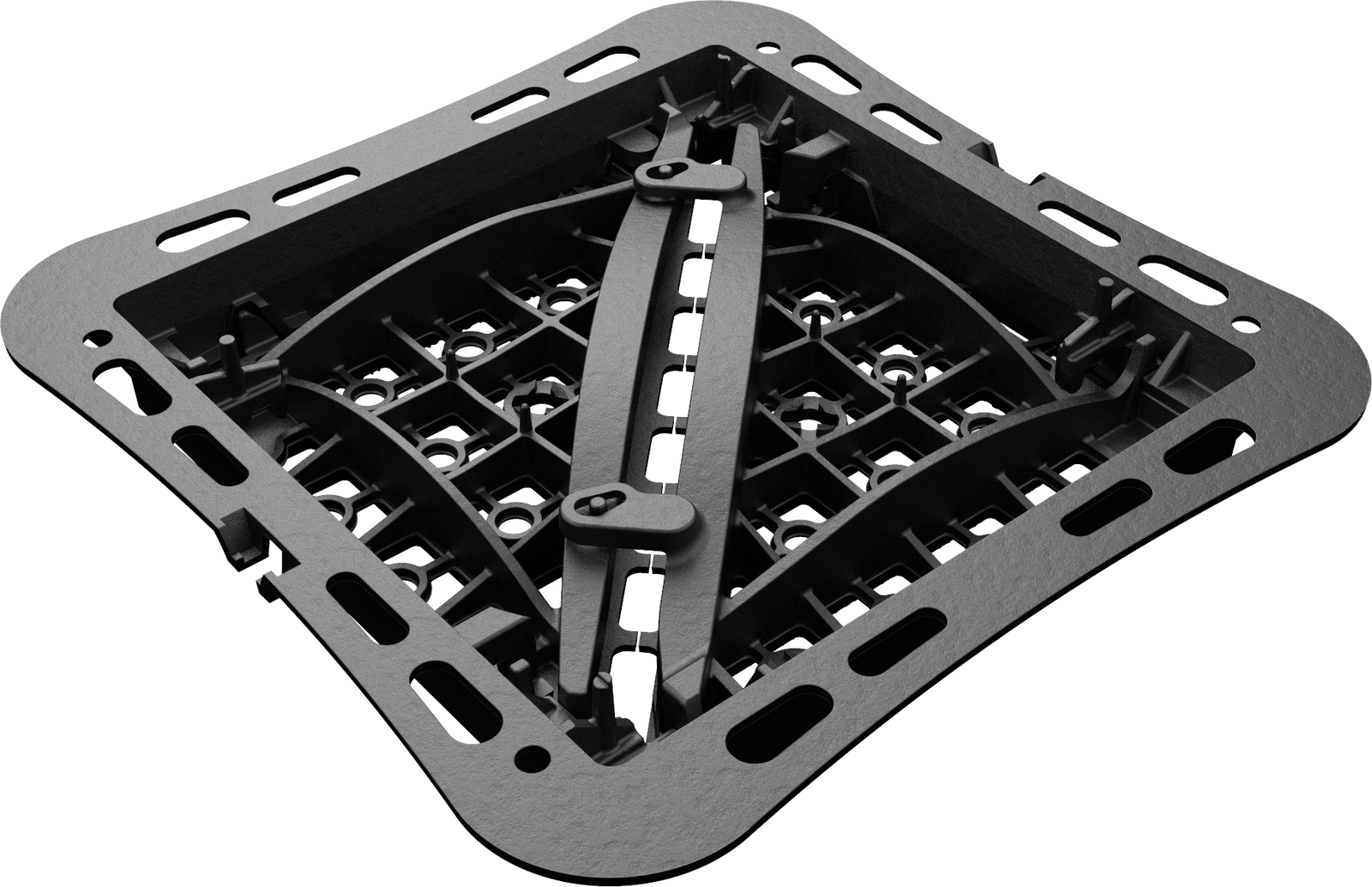

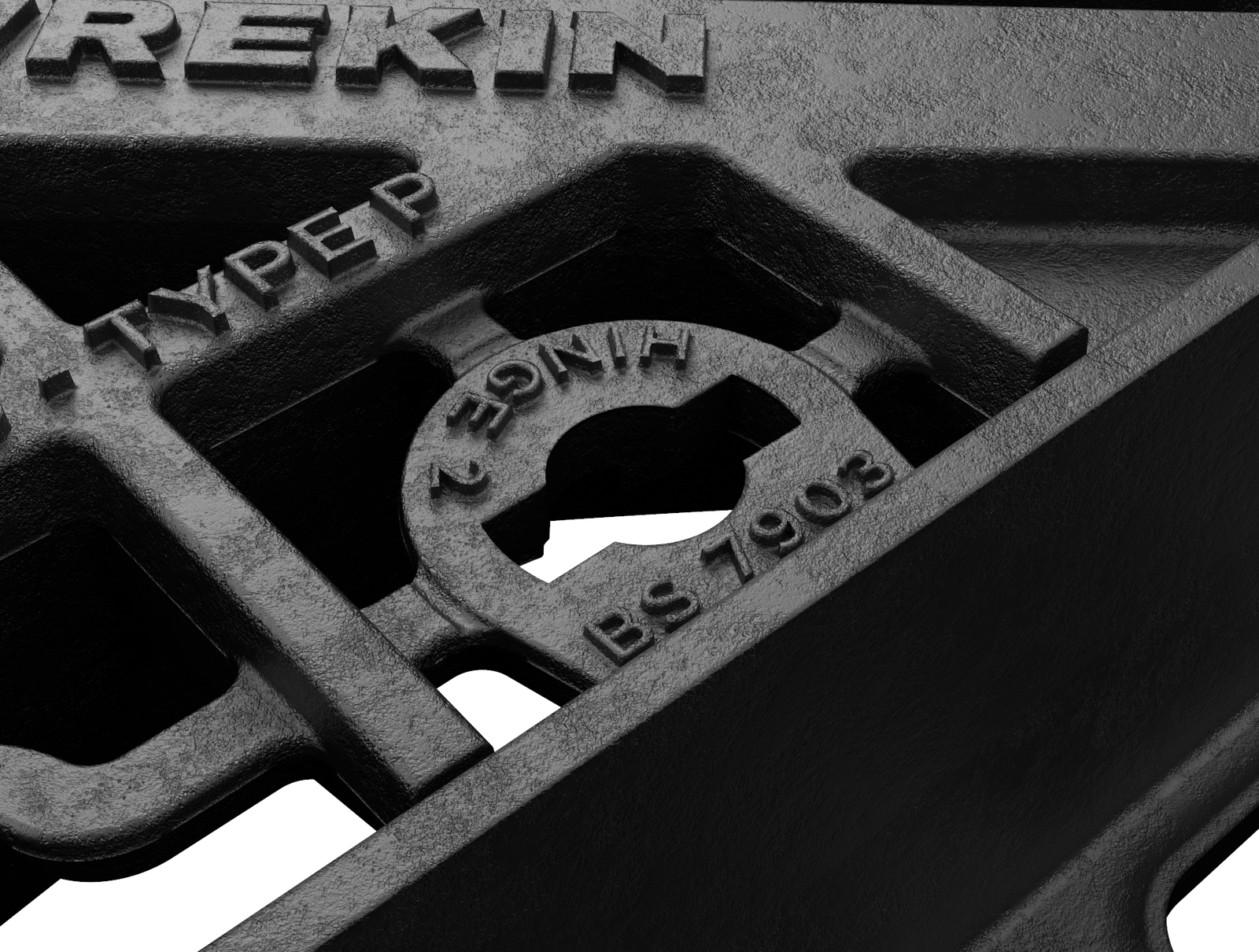

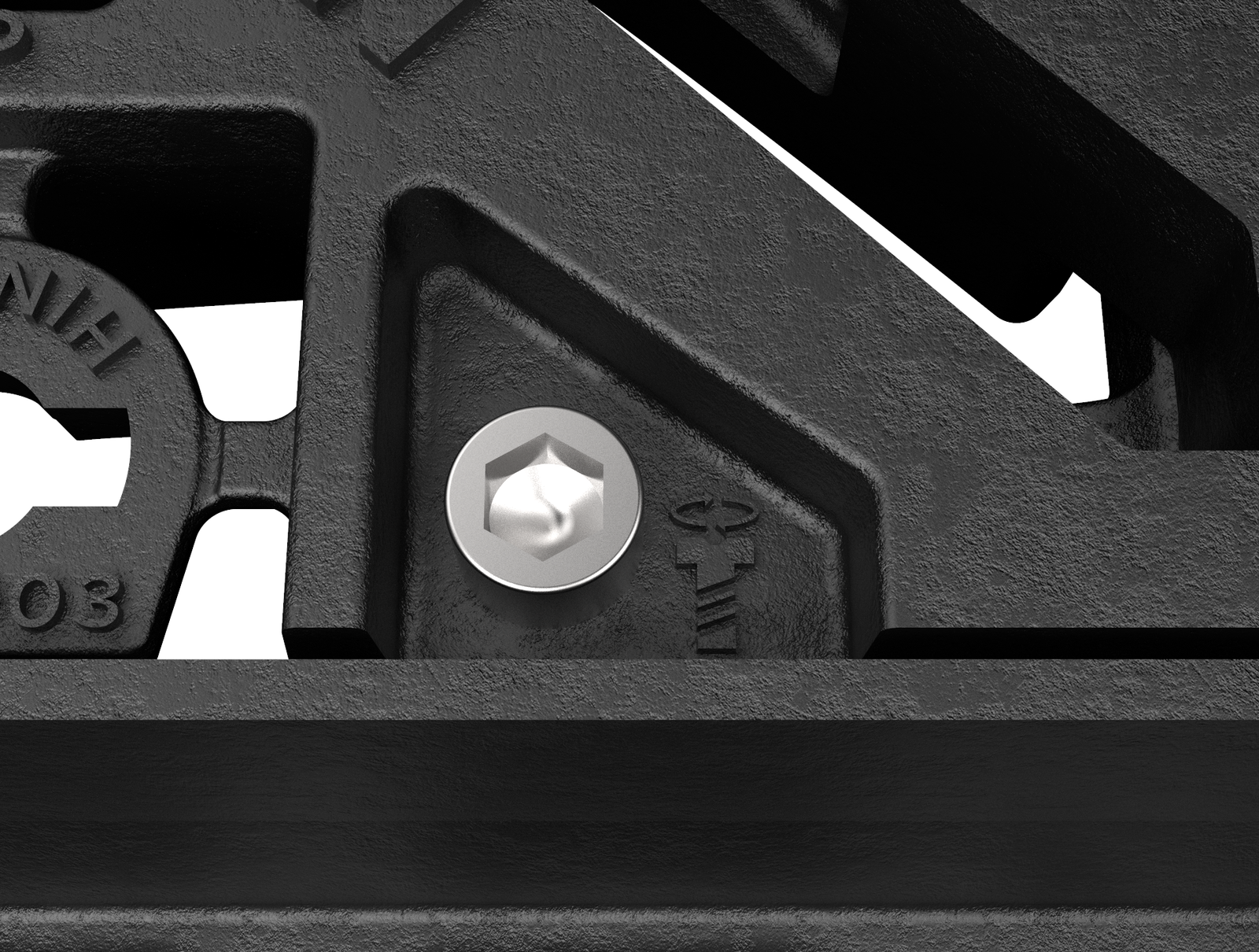

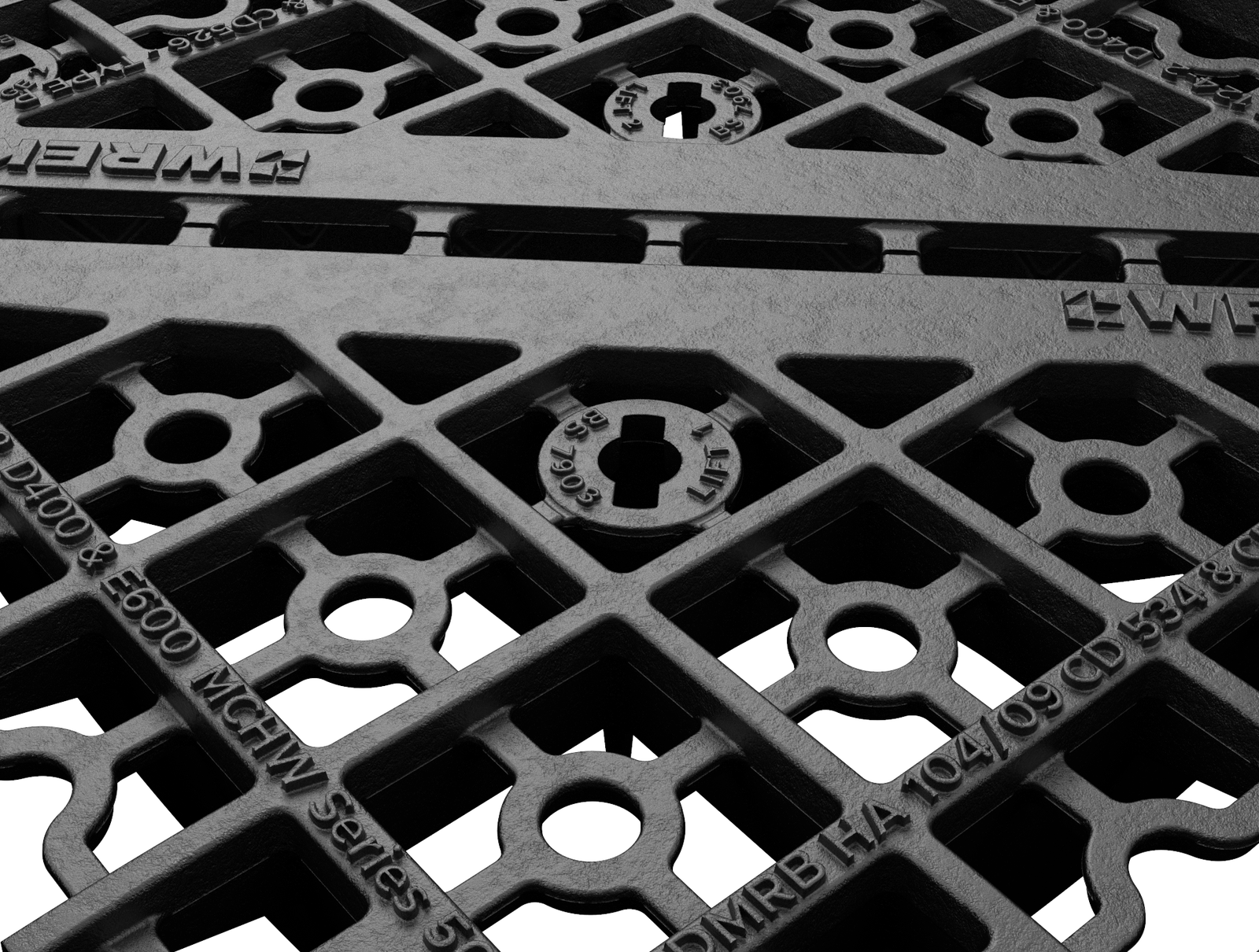

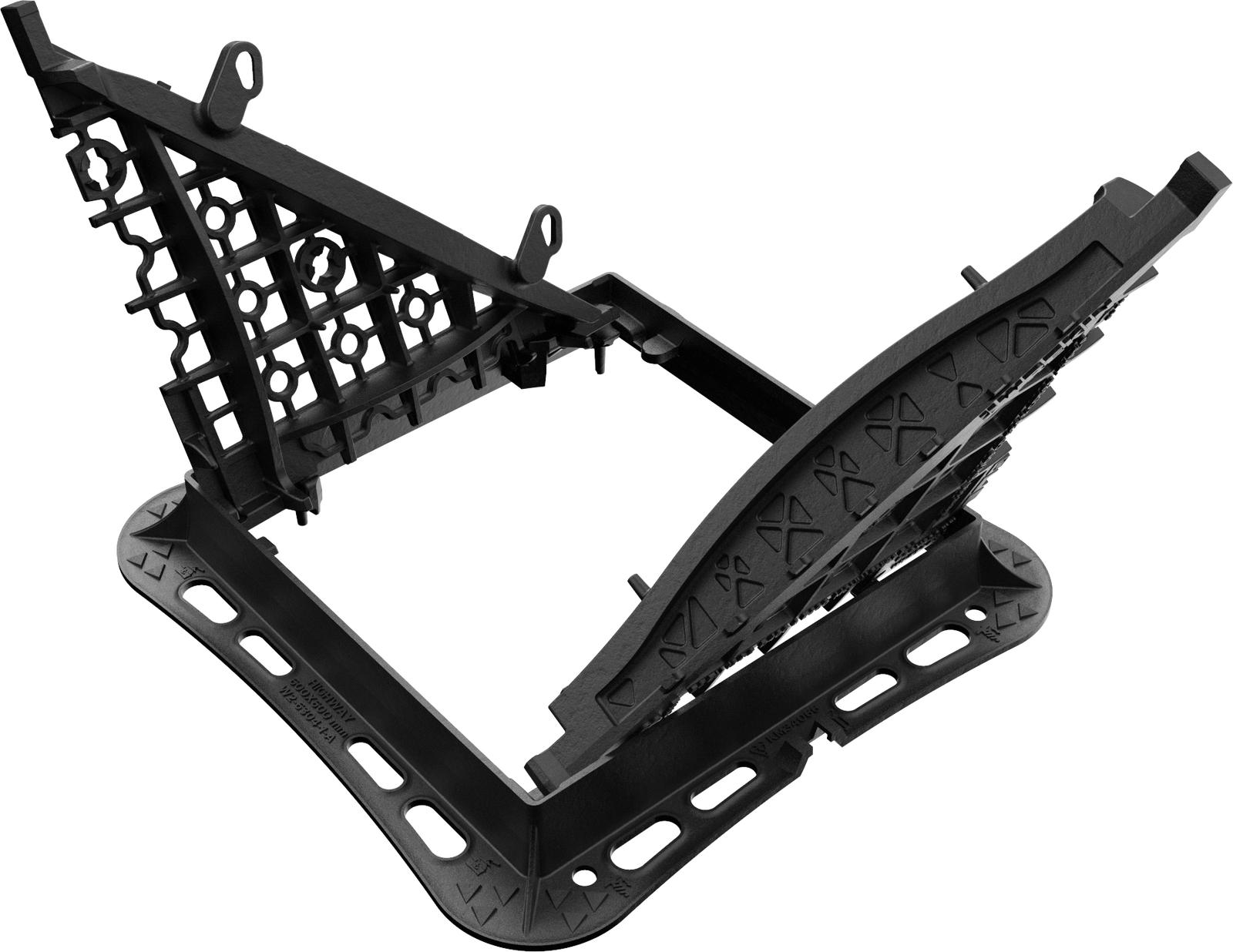

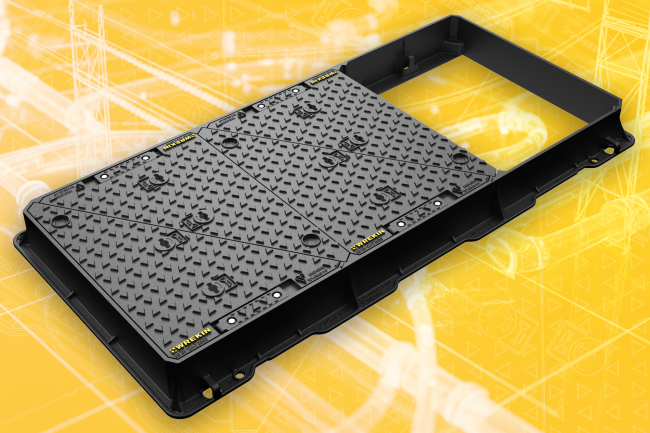

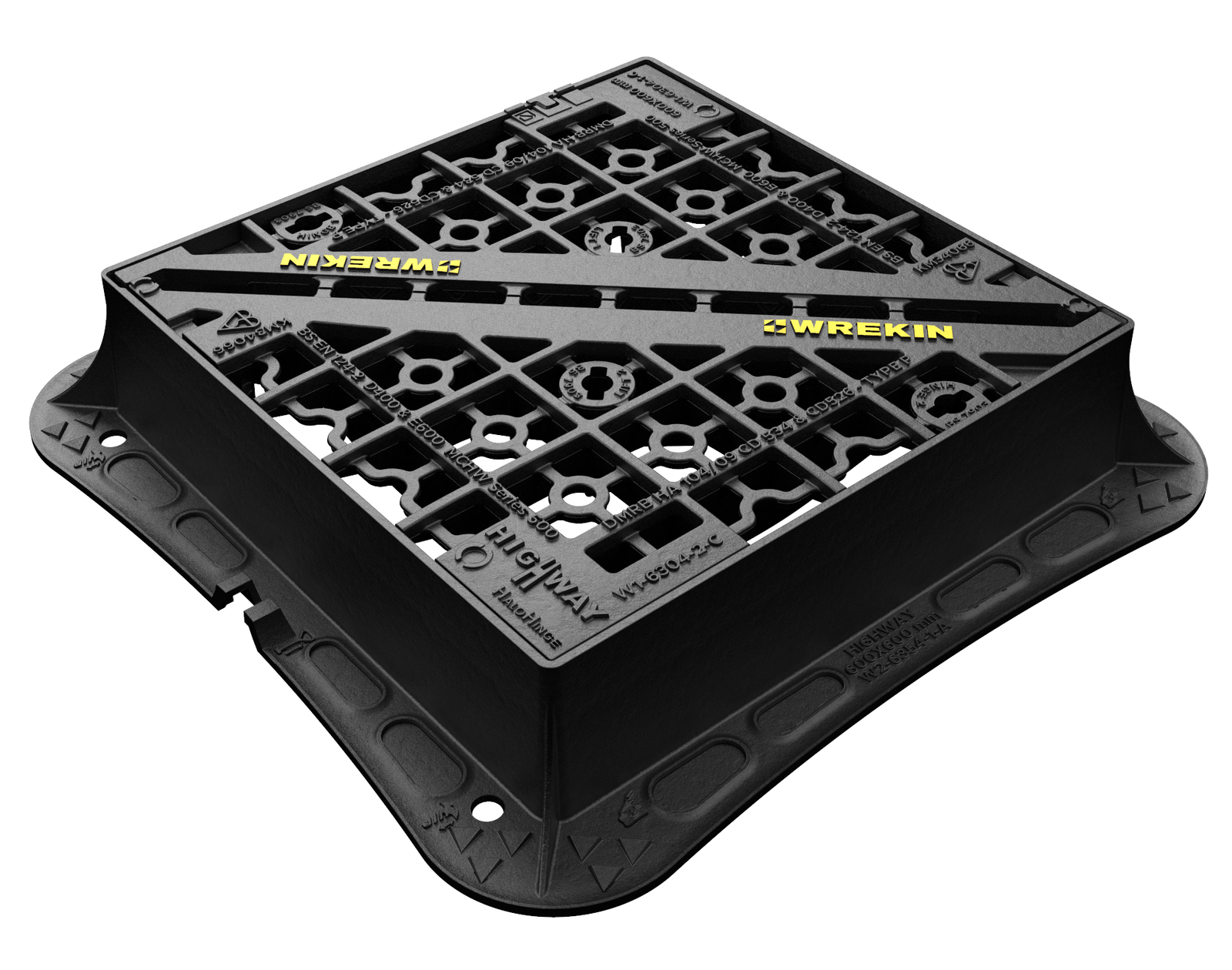

Innovative approaches to gully design are helping to address these issues. Maintenance-friendly systems that provide stability under heavy loads and allow for safer, easier access during inspections reduce the physical strain on workers. The E600 HaloHinge gully grate is one such solution, designed to lift and pivot on a hinge so that a single technician can safely carry out inspections or routine maintenance without needing a second person to lift the cover. This reduces the risk of injury and supports a safer working environment for highway maintenance teams. The benefits of smarter gully solutions extend beyond immediate safety improvements. Reduced emergency repairs and faster inspections, alongside more predictable maintenance schedules, translate into measurable efficiency gains. Local authorities can focus on broader road network management rather than constantly addressing physically demanding gully-related issues, protecting both staff and budgets. Ultimately, the conversation around gully maintenance is not about a single product, but it is about recognising the safety and efficiency challenges that local authority teams face and exploring solutions that allow them to work smarter. By prioritising durability and worker safety in gully systems, councils can reduce hazards and cut reactive maintenance all while ensuring roads remain safe and reliable for all users. For local authorities, investing in smarter gully solutions represents a practical way to improve day-to-day operations while protecting the public and safeguarding the health of maintenance staff. As traffic volumes grow and infrastructure ages, forward-thinking approaches to gully design and maintenance will be increasingly important for safer and more efficient road networks. Products

| ||||||||||||||||||||||||||||||