Blog

How a focus on improving ironworks could reduce the UK’s pothole problem

26 July 2024

In the winter months, it is hard to avoid mention of the UK’s pothole problem. A Google search shows over 16,000 news items on potholes and trends continue to show the search term is on the rise. But while potholes fall off the news agenda in the summer months this is actually the time where reports increase.

It is fair to say that whether we are walking, cycling, driving or managing our roads, we are all aware of the UK’s pothole problem. But what we are not aware of is how improving ironworks could reduce the UK’s pothole problem. How many potholes are caused by poor ironwork installations?Over six million manholes, access covers, and gully grates are located across the UK, which roughly translates into 60 ironworks per square mile. In 2010, Wrekin Products, together with Northern Ireland Water, Severn Trent Water, and Northumbrian Water, conducted a research report that analysed the number of ironworks failing across the UK. The research identified three main causes affecting ironworks:

Then, they reviewed these causes against a series of manhole covers, access covers, and gully grates to understand how many are affected. Analysing the data highlighted that:

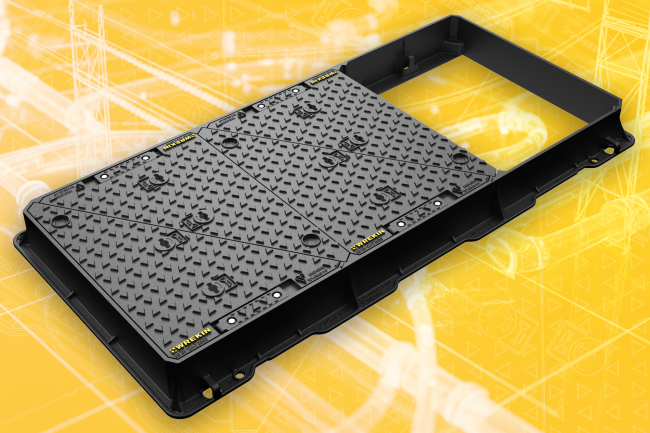

It also found that 44% of covers suffered a failure of the paved surround or the ground around the access cover or gully grate. To put that into simpler terms, this failure could become a pothole formation around ironworks. Top blogsImproving ironworks could reduce the UK’s pothole problemWhile there are other causes of potholes away from ironworks, such as heavier traffic and increased volume of traffic alongside the seasonal ‘freeze and thaw’ effect, the research indicates that local authorities could reduce potholes on their roads by focusing on improving ironworks. This approach dictates a shift in focus from a reactive to a proactive approach. Rather than focusing on filling the pothole after the ironwork has been specified, the longer-term, more effective option is to specify ironwork with more beneficial key features. These include: The right product for the jobSpecifying a manhole cover that covers your annual average daily traffic is important. For example, choosing an E600 access cover over D400 could prove to be a better choice for higher traffic volumes. Frame reinforcementIronwork should balance strength with performance while being engineered to exceed standards. Rigid i-beams and frame gussets are two critical features to review when specifying your ironworks. Low-wear seatingCover seating wear has been attributed as a major reason for failed manhole covers. A larger and higher seating position increases the resistance to general wear by minimising frame movement. Mortar sympathetic frame featuresSurface texturing above and below the flange enables better mortar engagement. Combined with a high cover seating position, it helps to minimise wear and frame flex. Frame adjustmentUsing either Screwlift or Uniform adjustment units to reliably adjust the frame when bedding. Focusing on the long term over patch repair helps local authorities break the cycle of resurfacing and filling cheaply and quickly, which can prove to be a false economy. Not only can this switch in focus reduce potholes, but it can also reduce long-term costs and environmental impact.

Potholes: More than a surface issuePOTHOLES - MORE THAN A SURFACE ISSUEHelping to find solutions to the UK's pothole problemPotholes across the UK’s road and highway network are a real problem. But did you know ironwork specification and selection can affect and even increase the likelihood of a pothole forming? Our new report explores;

Related products

|