|

CD 534: Chamber Tops and Gully Tops for Road Drainage and Services, now at version 0.2.0. is here Find out more

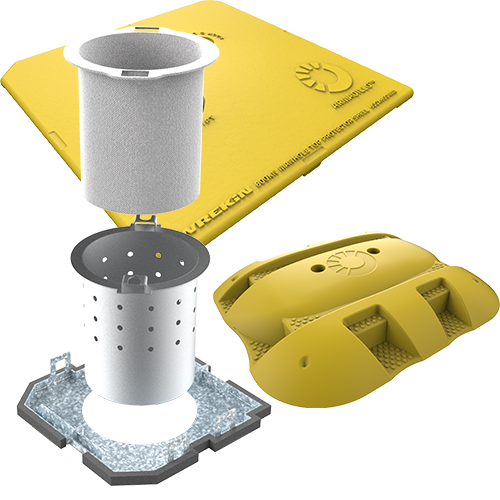

Rapid set bedding mortar Unipak®UniPak is a BBA HAPAS certified rapid-set, high-strength, polyester resin bedding mortar system developed, tested and proven for highway use. It is designed to prevent the most common causes of bedding failure, minimising disruption and inconvenience to road users while improving safety for operatives. Suitable for all BS EN 124-2 applications, it can be used on its own or with Uniform chamber adjustment units which are made from the same two-part polyester resin material, setting to form a highly durable structure.

Unipak avoids many of the problems associated with cement-based mortar and allows rapid road opening, curing in as little as 25 minutes. Simply mix both parts together for a consistent and repeatable result. Removing issues of performance loss due to operator judgement or personal mix preferences. With a very low slump factor, compared with other mortars, Unipak provide ironwork with support even in an uncured condition. Its low notch sensitivity provides crack resistance, which could be caused by any sharp or angular ironwork or tools. Unipak's unique colour allows it to be easily identified. Available in three tub sizes (6.5, 12.5 and 25Kg), it is easy to select the right for small surface boxes up to the largest of covers, reducing waste to a minimum. Comprised of two components (sold separately):

Overcome the common causes of bedding failure with UnipakConventional packing and cement bedding just aren't good enough for the job. Unchanged methods over a hundred years have to change. It's more important than ever to have an emphasis on service life, long-term economies and rapid road opening after work completion to reduce carbon emissions. Unipak provides the solution to these problems and more. WRc (Water Research Centre) and Nottingham University research observed that:

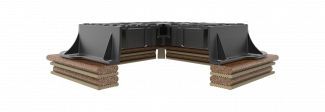

Rapid frame adjusmentUniform chamber adjustment unitsUniform overcomes many of the common issues of alternative packing methods which are often manufactured from wood pulp, resulting in swelling and weakness over time. Additionally, their smooth surfaces mean lateral forces break the mortar bond and angular edges result in the cracking of surrounding brittle foundation materials. Uniform chamber adjustment units are manufactured from the same materials as Unipak, ensuring compatibility and longevity. We offer chamber blocks in a 100mm width and two thicknesses (15mm and 25mm), which can be easily cut and fixed using conventional techniques and step wedges (up to 75mm in height, with 5mm increments) Both materials interlock with bedding mortar and resist lateral forces with no reliance on friction or mortar adhesion. Manufactured from the same compound as Unipak, they form an integral part of the system. These adjustment units are suitable for BS EN 124 highway applications, groups 1 to 4. Products

Potholes: More than a surface issuePOTHOLES - MORE THAN A SURFACE ISSUEHelping to find solutions to the UK's pothole problemPotholes across the UK’s road and highway network are a real problem. But did you know ironwork specification and selection can affect and even increase the likelihood of a pothole forming? Our new report explores;

More available accessories

| |||||||||||||||||||||||||||||