|

Understand the link between poor ironwork installations and pothole creation in our new whitepaper. Potholes - More than a surface issue Get your copy

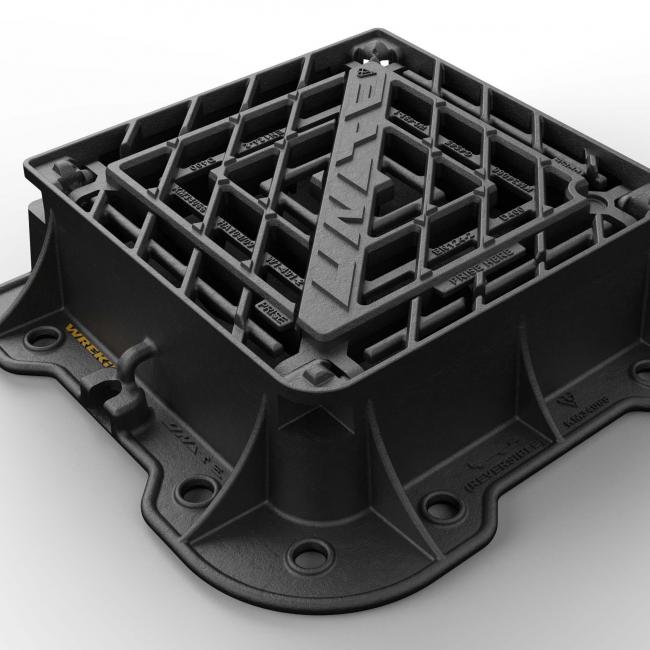

Simply the best-performing gully grates available, Unite has been installed more than 500,000 times to date – with no reported failures. Made from extremely durable and 100% recyclable ductile iron, Unite is packed full of unique design features to ensure an unrivalled lifespan. Unite brings thousands of pounds worth of savings across the lifetime the grating, while preventing unnecessary road disruption and lowering carbon emissions by reducing the number of replacements or repairs. Serving on highways for more than 20 years, the key to Unites success is how it minimises seat wear between the frames and the gratings, reducing failures. Unite has the stiffest grating structure in its class, making the seating less vulnerable to any movement caused by flexing during trafficking.

Unite D400 gully grating reduce whole life cost thanks to:

Gully grates

Unite 10 year warrantyWhen installed with either our Unipak polymer resin bedding mortar, or Instarmac Envirobed® CD534 flowable bedding mortar, the Unite range is available with a 10-year product warranty*. Due to its unique design and overwhelming success in the local authority and utilities sector, Unite is the proven choice for durability and longevity for highway ironwork installations. View further warranty information * Subject to terms and conditions

Create an installation that lastsSpecification clausesDownload and use our specification clauses in your future projects to ensure third-party installers use high-quality products. These documents provide clear, precise guidance for specifying our Unite and Highway product ranges, ensuring the best materials are always used in projects. By incorporating these clauses, you can significantly reduce the likelihood of product failure, extend the lifespan of ironwork installations, and minimise costly road closures and disruptions.

Potholes: More than a surface issuePOTHOLES - MORE THAN A SURFACE ISSUEHelping to find solutions to the UK's pothole problemPotholes across the UK’s road and highway network are a real problem. But did you know ironwork specification and selection can affect and even increase the likelihood of a pothole forming? Our new report explores;

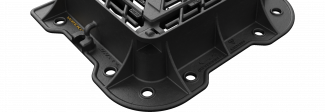

Rapid reversalHinged in 3 directionsGully gratings should always be hinged with the direction of traffic flow. However, if traffic is reversed on a street, gully gratings could potentially be hinging in the wrong direction. Typically gully grates would need to be dug up and reset, or even replaced entirely if the hinging direction isn't reversible. Unite gully grates accommodate 3 directions of hinging within the frame. This means the frame doesn't need to be dug up, the grating can simply be reversed within the frame.

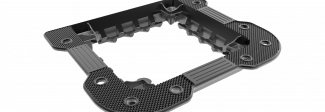

Fit and forgetTextured flange undersideThe underside of the frame flange has a textured surface. This surface increases adhesion to bedding materials by allowing the grating to use both the adhesive and mechanical properties of the bedding mortar. Holes are also in the frame allowing mortar to pass from the underside to the topside of the frame. This creates an interlock, securing the frame in place. These features, and more combine, to give Unite installations the lowest whole life cost of any ironwork available. In fact, we're so confident in Unite's longevity it's available with a 10 year warranty*. *Subject to terms

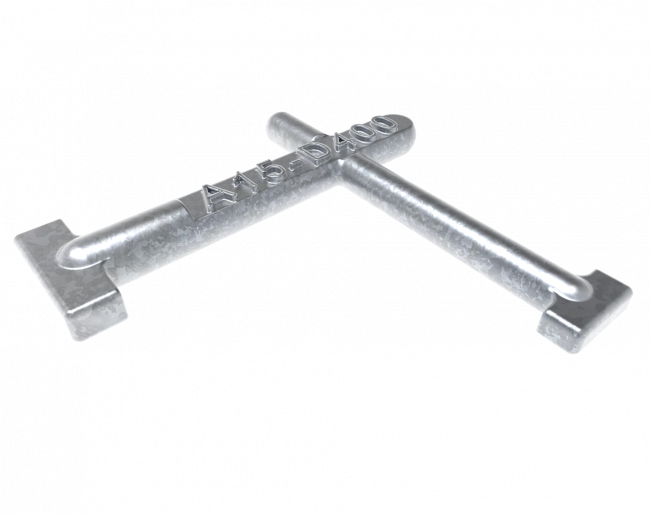

Help to dissipate the loadEnlarged frame cornersHeavily trafficked ironwork needs to be able to with stand extreme loads for a long time. Key to this is a solid foundation. The enlarged frame corners featured on Unite gully gratings are critical. During the development stages of Unite we analysed where forces are distributed within the frame. We found that the corners take most of the stress. To combat this we increased the surface area of the corners and added rounded frame edges to the circumference of the frame. The means loads and stresses are minimised and any vibrations are safely dissipated, as the smooth edges are more sympathetic to the bedding mortar. Unite™ range accessories

Contact usWhether you are looking for live project support, or are in the initial stages of specification, we are always on hand and happy to help. | ||||||||||||||||||||||||||||||