|

CD 534: Chamber Tops and Gully Tops for Road Drainage and Services, now at version 0.2.0. is here Find out more

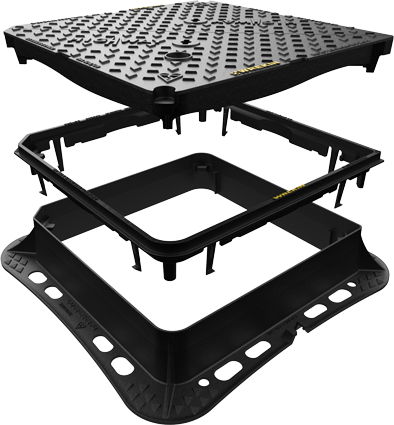

Our products Clicklift™Clicklift removes the time and resources required to dig out and reinstall manhole frames to suit the final adoptable road surface. This eliminates the potential damage to manhole covers during construction, minimises disruption and removes the potential for residents claims for damage to their vehicles.

Ready, steady, Clicklift!

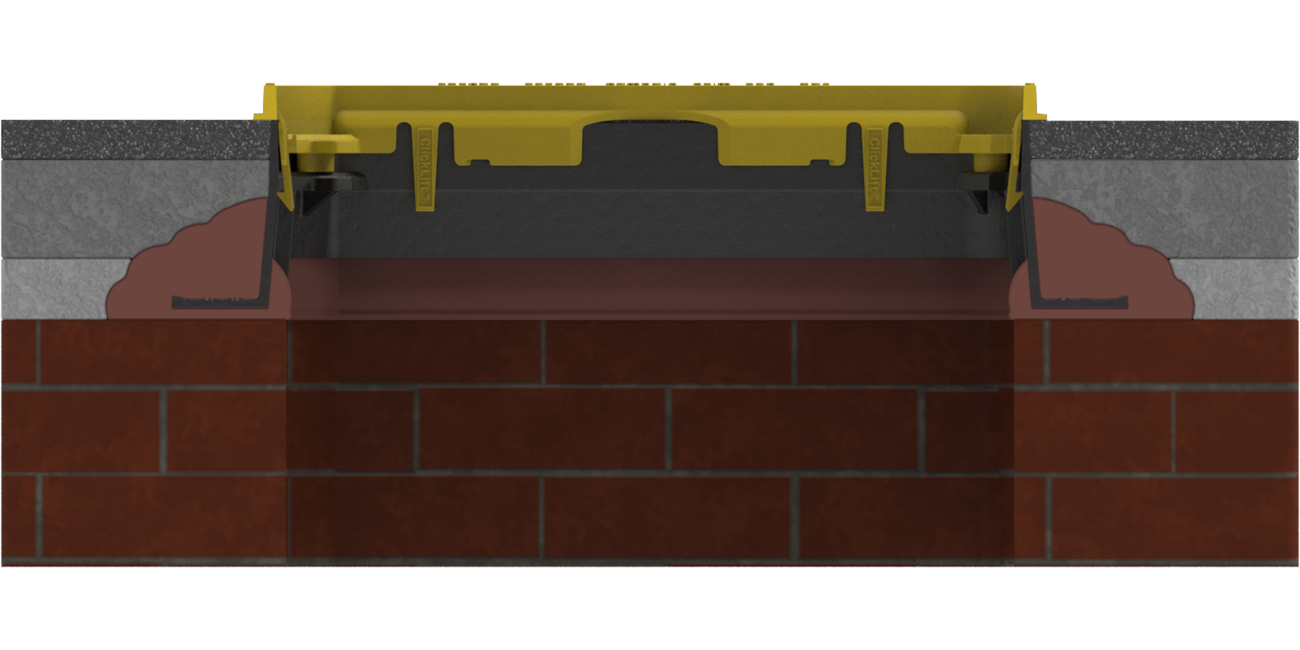

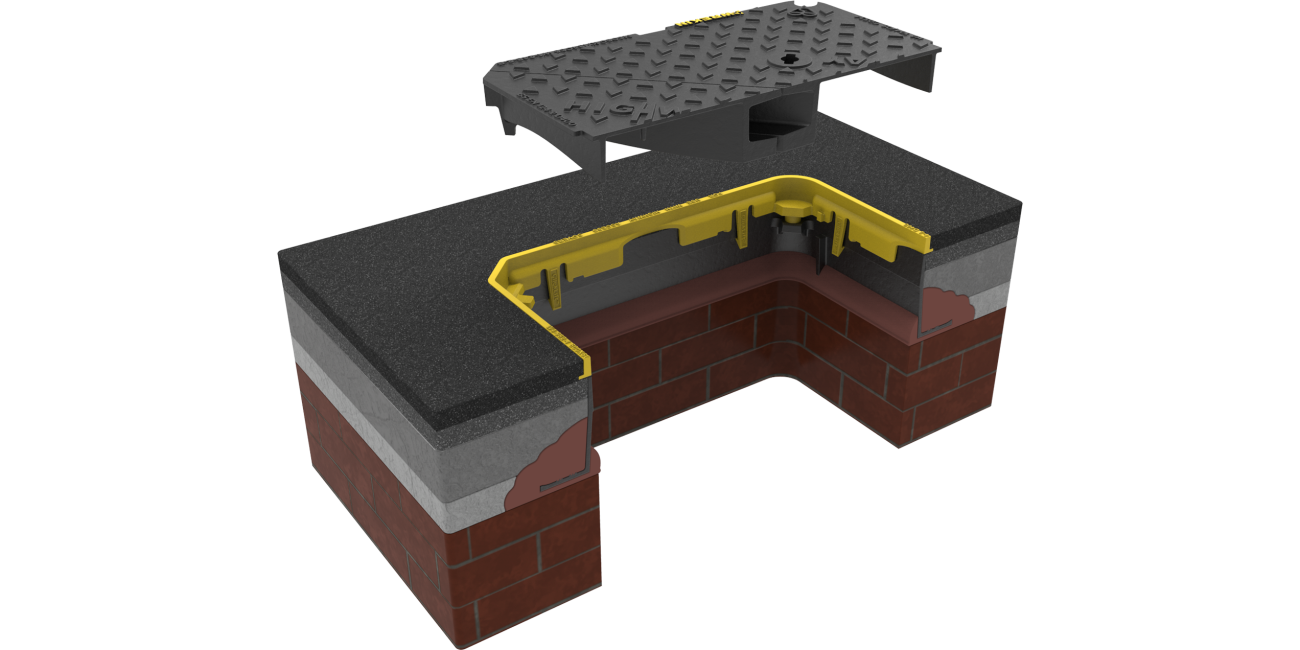

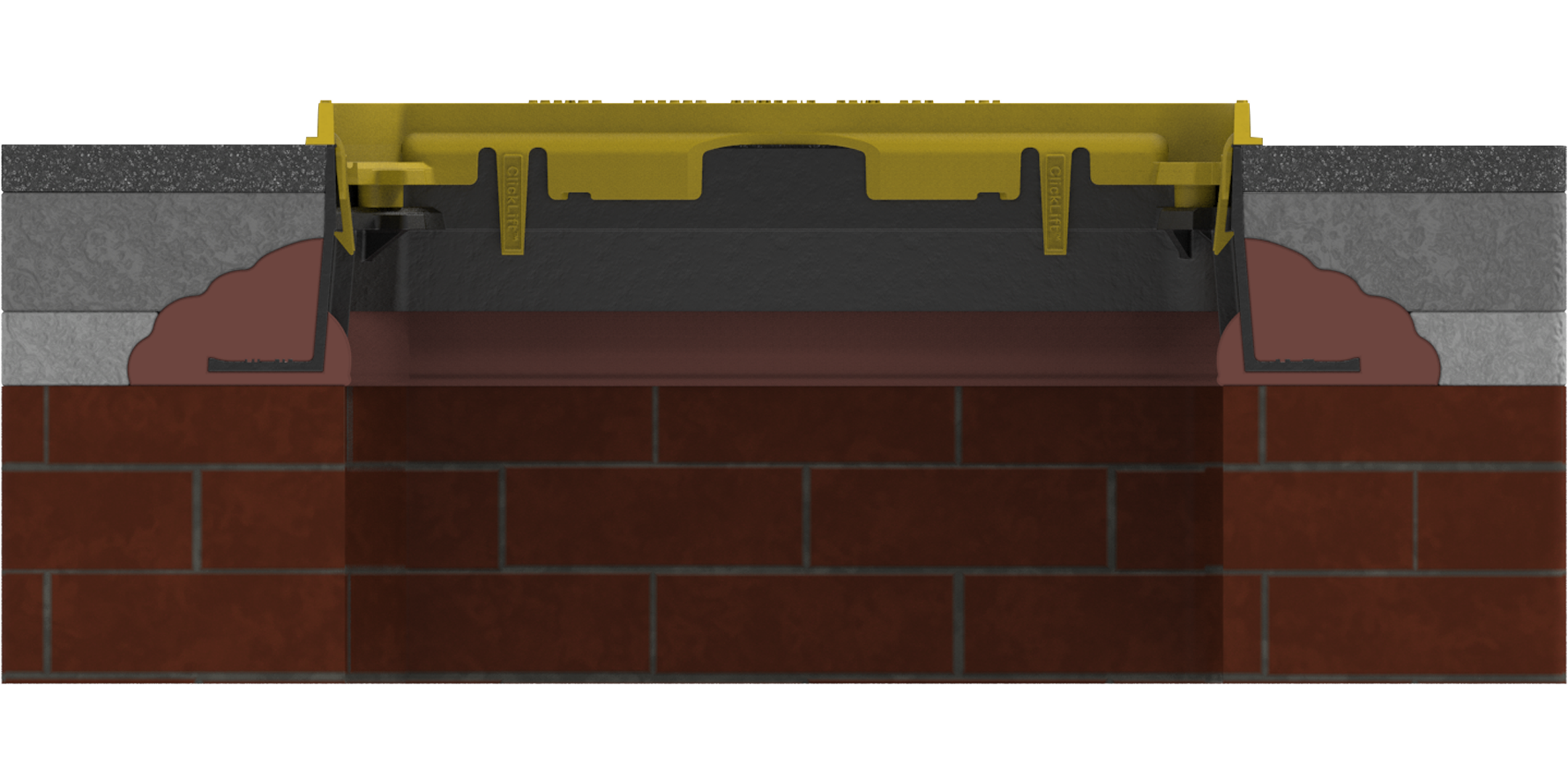

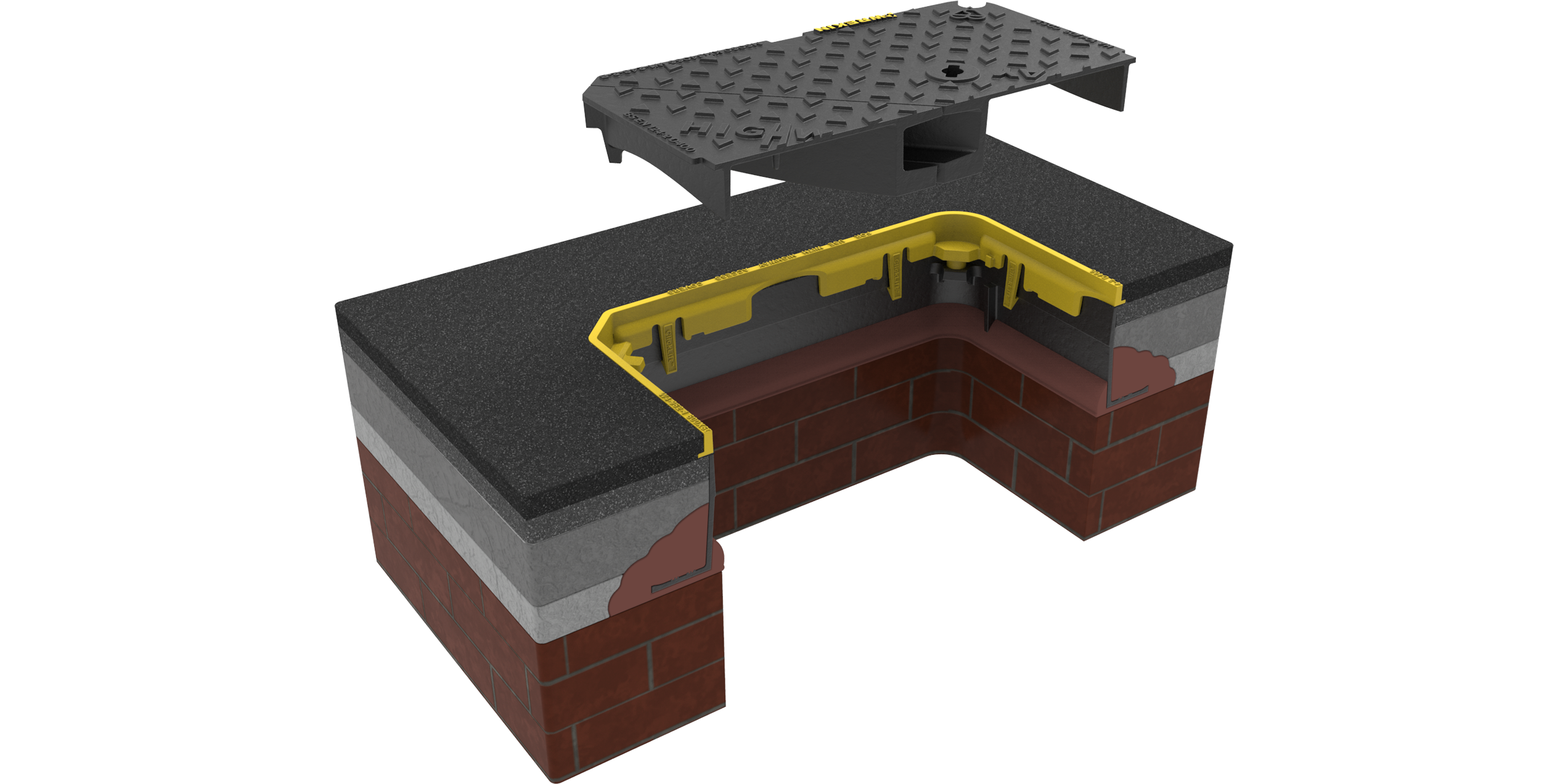

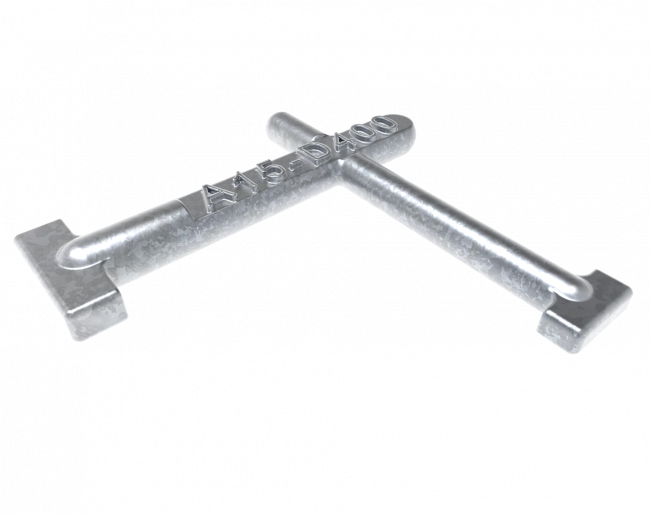

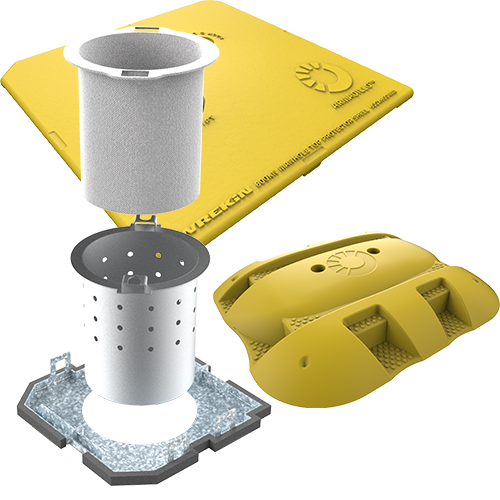

Introducing Clicklift, a fully kitemarked system that offers housing developers and contractors significant savings in terms of time, money, and hassle. With Clicklift, entire estates can have their covers raised to the final surfacing level in just a few hours, without the need for digging out and re-installing manhole frames. Clicklift raises 600 x 600mm and 675 x 675mm Tristar and Highway manhole frames to suit the final surface layer. It can be installed with minimal tools and requires no skilled labour, thanks to its simple and rapid installation process. This innovative system is available with four fixed incremental raising heights, namely 30mm, 40mm, 50mm, and 60mm. By using Clicklift, contractors and developers can enjoy significant time and cost savings while eliminating common nuisance issues for residents on new build developments. *This means the installer will need to pay particular attention to the height and alignment of the frame on installation (taking into account any camber or gradient of the road and the level of the final surface layer). Simple rapid installationWhat makes Clicklift stand out is its simplicity and speed of installation, requiring minimal tools. It really is as easy as clicking the Clicklift component into a Highway or Tristar frame. It raises the frame to the final adoptable road surface. You can see how quick and effortless the installation process is for yourself. In addition to its ease of installation, Clicklift also offers a robust and durable solution that can withstand heavy traffic up to D400 load class. It is a reliable and cost-effective option that is ideally suited to new build housing estates, where it can save significant time, money, inconvenience and carbon during installation. Overall, Clicklift is a revolutionary solution for those looking for a fast, efficient, and reliable way to install manhole frames on road surfaces. Option 1 - High damage risk

The cover is installed proud of the binding layer, leaving the manhole cover frame susceptible to construction traffic damage. Option 2 - The dig out, expensive and disruptive

The cover is installed level with the binding layer. To raise the cover to the level of the final surface layer (typically 30-60mm) it is then necessary to dig out the entire unit with all the associated costs and complications. Success storyOrchard Croft, DissBarconn Ltd.Clicklift was installed on a new build development it Diss, Norfolk. Clicklift allowed the contractor to raise the ironwork on their previously installed manhole covers in just 30 minutes, on a road that would have previously taken 2-3 weeks. It removed health and safety issues, such as working in confined spaces, and required no special training for the operatives. In addition the property developer benefited by removing the the need for letter drops and the management of residents parked cars. Products

More available accessories

| |||||||||||||||||||||||||||||||||||||