|

Understand the link between poor ironwork installations and pothole creation in our new whitepaper. Potholes - More than a surface issue Get your copy

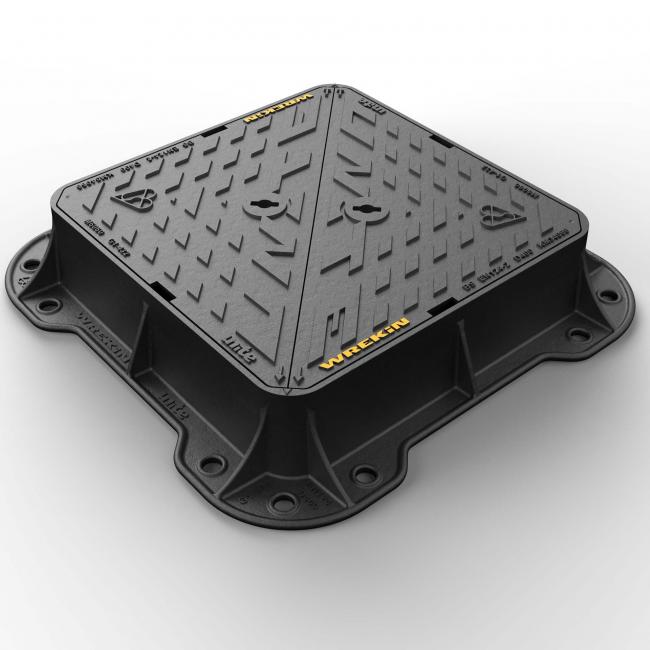

A quality above the rest Unite™ D400 manhole coversSimply the best D400 access cover range available in the market, in fact it's so good Unite is available with a 10 year warranty*. Packed full of design features that combine to give Unite the longest life and lowest whole life cost of any D400 access cover available. Designed and manufactured to exceed BS EN 124 and Highways England’s Design Manual for Roads and bridges (DMRB) specification CD 534 v0.1.0.

Over the course of 40 years we have a deep understanding of pavement and highway ironwork performance. Using the very latest tools and software, the Unite range of manhole covers have been engineered for extremely long life. Key to Unite’s longevity is minimising seat wear between covers and frames. The range has the stiffest cover structure in its class and on top of this, seating which is less vulnerable to any movement caused by cover flexing which may take place. We're so confident in Unite's performance, it's available with a 10 year warranty1. Unite has been designed to work sympathetically with bedding mortars, reducing stresses on the frame foundation, which has been identified by WRC as a major cause of manhole cover failure.

Square and rectangular manhole covers

Create an installation that lastsSpecification clausesDownload and use our specification clauses in your future projects to ensure third-party installers use high-quality products. These documents provide clear, precise guidance for specifying our Unite and Highway product ranges, ensuring the best materials are always used in projects. By incorporating these clauses, you can significantly reduce the likelihood of product failure, extend the lifespan of ironwork installations, and minimise costly road closures and disruptions.

Unite 10 year warrantyWhen installed with either our Unipak polymer resin bedding mortar, or Instarmac Envirobed® CD534 flowable bedding mortar, the Unite range is available with a 10-year product warranty*. Due to its unique design and overwhelming success in the local authority and utilities sector, Unite is the proven choice for durability and longevity for highway ironwork installations. View further warranty information * Subject to terms and conditions

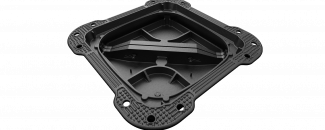

Mortar ‘gripper’ systemEffectively interlocked with bedding materialUnites flange surface provides a textured finish for bedding mortar to adhere to and the holes allow for interlocking between both sides. This will enable Unite to utilise the mechanical properties of bedding mortar, not just its adhesive characteristics. The built-in bevelled frame edge as standard, prevents sharp edges from cutting into and breaking mortar away over time, as vibrations from traffic are transferred into the foundation. These unique, mortar-sympathetic, and advanced design features, allow Unite installations to stand the test of time in extreme environments.

Large cover seating areaIncrease your asset lifeCover seating wear has been attributed as a major reason for failed manhole covers, which can lead to rocking, unwanted noise and eventually, failure. To further increase the lifespan of our Unite range, we have included a larger cover seating area. This increases the resistance to general wear by providing a large interface between covers and frames. In addition, we seat our covers as high up the frame as possible. This minimises frame movement, which otherwise would be transferred through the frame to the flange and bedding mortar, causing premature failures.

Locking bolt provisionProvide controlled accessOur Unite range can improve site security and provide security from theft and malicious damage or unauthorised access, with the addition of a factory-fitted locking bolt. In order to provide controlled access, Unite access covers can be supplied with robust factory-fitted screw fasteners. A specifically formed recess is provided for this purpose.

Flood and odour controlRetrofittable sealing platesUnite manhole covers are fully compatible with our range of No Leak and Low Leak sealing plates, thanks to the built-in internal accessory receiver. This internal skirt provides a sealing face to mate with different specifications of seal plate, depending on the application requirements (only available on products with reference ending in "/KUE"). This simple solution provides easy, effective and retrofittable flood and odour control to access chambers. It does not need to be specified at point of order, unlike nearly all flood and odour plate alternatives. Achieves compliance to Class 3 leak tightness performance in accordance with Table 1 of Section 2 within WIS 4-26-01 when fitted with no leak (/NL) sealing plate.

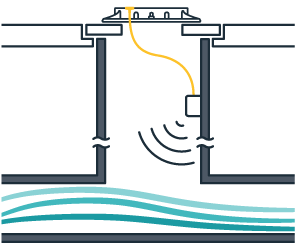

Only with WrekinRetrofittable antenna optionsUnite* and Highway access covers are the only ranges on the UK market to include provisions for communications equipment, such as antennas, to be installed within the cover.

The ID bolt provision can be used for antennas, allowing communications equipment, such as water meter monitoring, to be installed within a chamber beneath a cover whilevproviding a strong signal above ground without the need to dig or adjust the surrounding road surface. Saving significant time, effort and money while minimising disruption. * references ending /KUE Unite™ accessories

Contact usWhether you are looking for live project support, or are in the initial stages of specification, we are always on hand and happy to help. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||