Blog

Key Tips for Ironwork Installation: Ensuring Strength, Safety, and Durability

07 August 2024

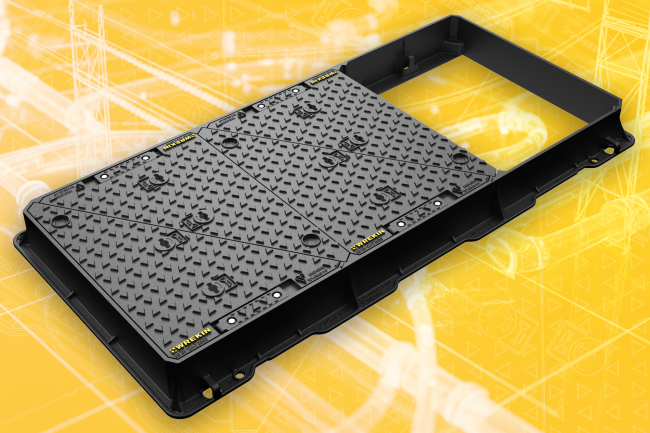

Wrekin Products is not just a supplier; we're your partner in ensuring that every installation is a testament to strength, safety, and durability. Here are eight key tips that every professional should follow for flawless ironwork installation. Reference the Gold StandardAlways consult the latest edition of British Standard BS7903. This document provides comprehensive guidelines on protection, load selection, and installation materials. It's the gold standard for ensuring that your work not only meets but exceeds expectations. Wrekin WisdomFor do's and don'ts before you start, check out our ironclad advice on frame placement, sizing, and support. Our do's and don'ts guide is an essential resource for avoiding common pitfalls and ensuring your ironwork stands the test of time. Foundation FundamentalsThe chamber top or slab structure must be rigid. It should be broad enough to support the entire ironwork frame flange along with its bedding mortar. This is the bedrock upon which the integrity of your installation rests. Top blogsPrep Work PrevailsEnsure that your chamber top or slab is not only clean and dry (for polyester resin mortars) but also has a textured surface to provide a key with the bedding material. The surface condition is pivotal for the adhesion and longevity of the installation. Bedding Depth - A Critical MeasureAim for a bedding depth immediately beneath the ironwork of approximately 25mm. This thickness is the sweet spot for load absorbance, distributing stress and preventing damage to the infrastructure below. The Curing ConundrumPatience is more than a virtue; it's a necessity. All structural installation materials must be fully cured before exposing them to service traffic. This waiting period ensures that the installation can withstand the rigors of its intended use. Ironwork Intelligence - Design MattersSelect an ironwork design with a foundation-friendly frame profile and operation. This decision can significantly influence the installation's integration and performance within its environment. We have a huge range of access covers for every scenario. Find out which to choose here. Material Mastery - Bedding MaterialChoose a bedding material that boasts not just good compressive strength but also excellent tensile and flexural strength. These properties are crucial for the material to withstand dynamic loads and prevent cracking. Installation Excellence with Wrekin ProductsRemember, the success of ironwork installation lies in precision, expertise, and the quality of materials used. Wrekin Products brings forty years of experience to the table, offering unparalleled design, service, and technical know-how. We stand ready to support you with advice and premium products tailored for every project's unique challenges. As you embark on your next installation, install with confidence, knowing that you have the backing of our expertise and the peace of mind that comes from using products designed for excellence.

Related Products

|